Manufacturing planning system in mechanical engineering

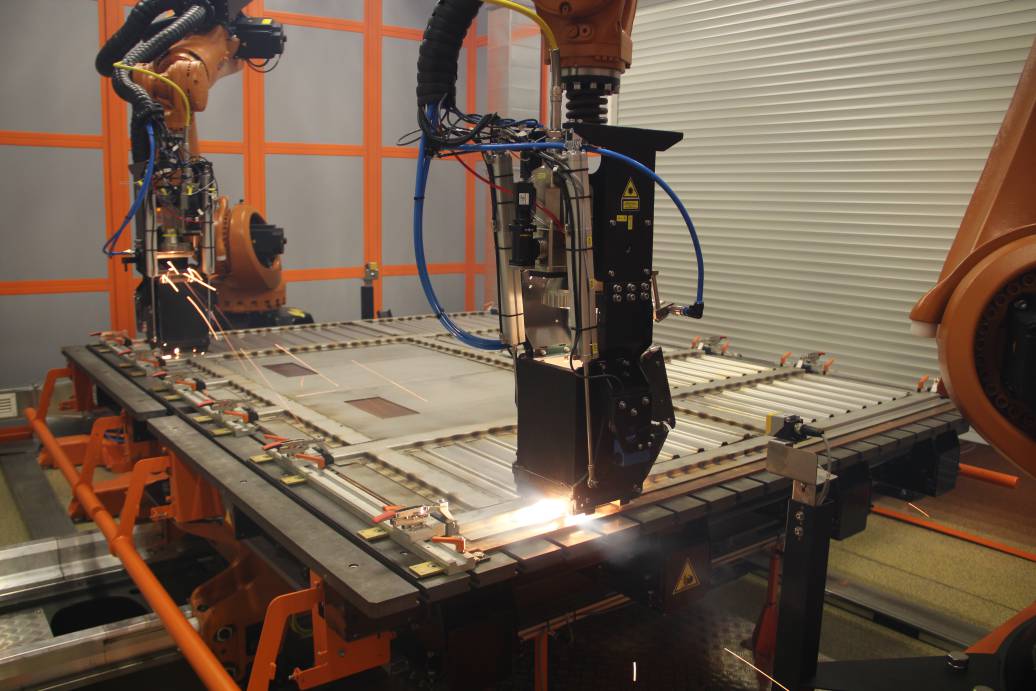

Software for manufacturing distribution in the areas of metal sheet laser and plasma cutting.

Task

The purpose of developing the software is to optimize the manufacturing programme shaping for available production sites, considering the technological characteristics of laser and plasma metal cutting.

The software is designed to provide a high material utilization rate (MUR) for cutting files included in the manufacturing programme, which would reduce the industrial waste volume. Making allowance for the increase in material charge, reducing the consumption of raw materials can significantly boost the economic efficiency of an enterprise.

The system will provide:

- Determining the target MUR in the long term;

- Aligned planning of long-term, spot, and urgent orders;

- Orders distribution by equipment interchangeability groups, taking into account the equipment operating modes, schedules of scheduled preventive and autonomous maintenance;

- Calculation of the economic benefit of optimizing the manufacturing programme, considering logistics costs and changes in MUR.

Solution

The system will allow to redistribute orders for the individual parts manufacturing between enterprises of the same holding company so that the location of parts on the cutting sheet during each operation is optimal for each of them.

Thus, the material utilization rate (MUR), a cornerstone in optimizing mechanical engineering manufacturing processes, increases. With the increase in MUR, industrial waste volume reduces, which in turn reduces expenses and increases the economic efficiency of an enterprise. Given the growing demand for raw materials, an increase in the average MUR even by a few percent will lead to substantial saving.

Software development uses advanced digital and industrial technologies at the junction of the following scientific disciplines: applied mathematics, information technology, cybernetics, and artificial intelligence. This set of methods allows to solve complex optimization problems that are relevant for both the scientific community and industrial enterprises.

By now, the reference algorithm has been developed and implemented. It connects all system parts and performs direct optimization of the manufacturing programme. The first tests have already been carried out, according to the results of which the increase in the planned MUR is 6-8%.

The program algorithm can be divided into two parts:

- Processing the parts from several production sites requirement plan and subsequent optimization of their distribution according to cutting files.

- Distribution of the received cutting files by manufacturing capacity.

The algorithm for processing the parts requirement plan combines manufacturing programmes from several sites and then divides them into groups according to the number of parts needed to be produced. The resulting groups are re-divided by metal types and sent to a third-party system for layout by cutting files. The cutting files are analyzed in terms of the material utilization rate. The rejected cutting files are re-processed considering the possibility of manufacturing at an earlier period or replacing the material, if there is such an opportunity.

At the next stage, an algorithm for distributing parts across sites is launched, which allows to take into account the work shifts schedule, time for equipment changeover, equipment repair and replacement, as well as a reserve for emergency orders. The distribution of cutting files allows for the technological characteristics of processing a particular type of metal and the technical features of the equipment. The requirement programme is distributed sequentially across the available manufacturing capacity, which allows efficient use of resources and avoiding downtime.

Project stages

During the first stage (2021-2022), we have managed to develop:

- the basic algorithm that ensures the distribution of orders according to the main manufacturing programme;

- the algorithm of accounting for the equipment operating time schedule;

- the algorithm considering different sheet formats of the same metal type;

- the algorithm of accounting for urgent orders with subsequent redistribution of manufacturing capacity.

The first stage of the project has been completed and is undergoing customer's functional testing now.

During the second stage (2022), it is planned to:

- design a service for calculating several manufacturing programme variants, taking into account parameter design to compare the results;

- integrate a software with 1C:ERP in terms of automated exchange of data on orders and the received manufacturing programme;

- develop a new frontend software solution according to the Customer's expectations.

Technologies

| Software programming languages: | C#, javascript |

| CAD | Autonest 18 |

| Software platforms | .net Framework 4.7, AngularJs |

| Database | MySQL |

Intellectual Property

Project team

The development is carried out by a joint team of Digital Modeling of Industrial Systems Laboratory and Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center in cooperation with Tetrakub LLC and 2050-Integrator LLC, NTI consortium members.

- Project Manager: Gintciak A.M., Head of the Digital Modeling of Industrial Systems Laboratory of the SPbPU NTI Center

- Development Team Lead: Uspensky M.B., Candidate of Technical Sciences, researcher at the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center

- Analytics Team Lead: Burlutskaya Zh.V., Junior Researcher at the Digital Modeling of Industrial Systems Laboratory of the SPbPU NTI Center

Subcontractors

- 2050 Integrator LLC

- Tetrakub LLC