VR lab for modeling portal crane operation

An interactive training and demonstration system has been developed for the purpose of studying the design and operating characteristics of a portal crane.

Task

The training virtual demonstration system ‘Study of complex articulated jib systems using a portal crane as an example’ was developed as part of the Education Quality Improvement and Personnel Training Programme (2022-2023) for Gazprom PJSC/Peter the Great St. Petersburg Polytechnic University (SPbPU)

The goal of this project is to improve the educational process in Gazprom's core training areas at the Higher School of Transport of the Institute of Metallurgy, Mechanical Engineering, and Transport of SPbPU.

A VR application is developed to study kinematics and power factors in articulated jib systems using a portal crane as an example. The purpose of the application is to give a better understanding of the principles of articulated jib systems, the relationship between geometric and power parameters in them, and the study of portal cranes.

The system allows simulating operational loads on the basis of the integration of the mathematical model of the articulated jib system with the virtual model of the crane.

The mathematical model permits the variation of different geometric and power input parameters, which are visualized in the virtual model. This provides an understanding of the principles of complex geometrically variable systems and assists in learning how to correctly select initial parameters for newly created machines. This system enables the visualization of what can be obtained based on the data selected by the student.

The virtual model was constructed on the basis of the actual Gazprom facility located in the Peledui port.

Solution

3D models of a portal crane in a virtual environment (port, waters, dry cargoes, containers) were created for the virtual laboratory. Software implementation of the virtual space was performed. An operation scenario was also developed: a student, having previously studied the theory, independently selects the parameters of the jib system in the application and receives a visualization of the crane's operation while controlling it.

The virtual model prototype was the Kirovets transshipment portal crane manufactured by Tekhnoros PA, which is one of the main types of cranes used in sea and river ports in Russia. The crane is characterized by a robust, intelligently designed construction that enables it to operate in all weather conditions. The cargo berth of Gazprom in Peledui village on the Lena River in Yakutia was selected as a prototype for creating a virtual environment.

The VR application employs a mathematical model of a portal crane developed by employees of the Higher School of Transport of the Institute of Machinery, Materials, and Transport of SPbPU. The mathematical model is constructed on the basis of an analysis of the movement patterns and load distribution of crane components. The ISSDP Laboratory developers have implemented a software module to integrate the mathematical model into the VR application, allowing for real-time execution.

Upon initiating the process, the user configures the basic components of the crane, thus setting part of the input data for the mathematical model. The remaining parameters (current outreach and weight of the cargo to be carried) are calculated and adjusted in real-time during the crane control process.

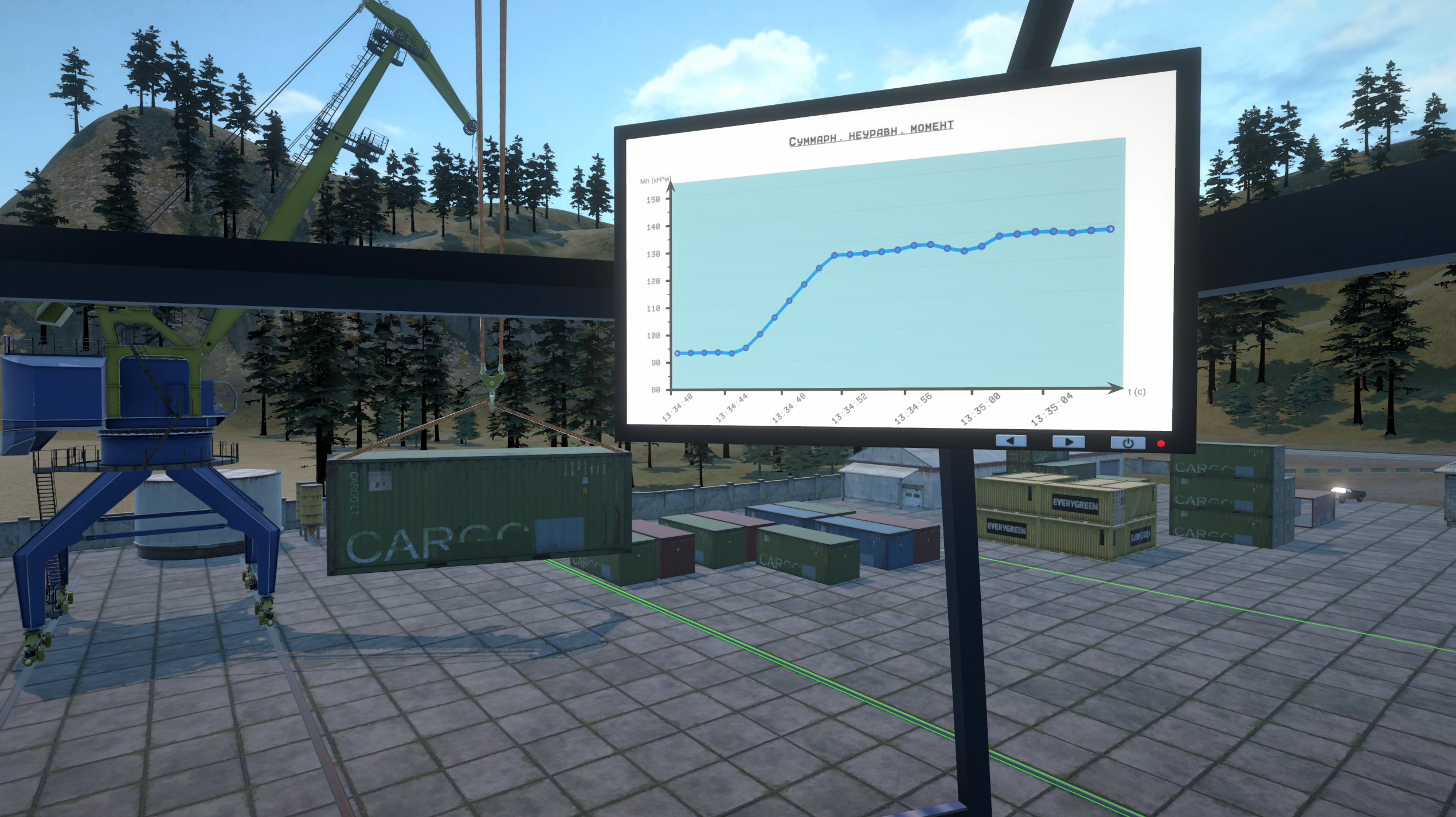

The output data of the model represents parameters that indicate the impact on the crane components in response to the given input data. The values of the individual indicators are calculated on virtual displays and visualized by means of graphs and a color highlighting system. Graphs are employed to illustrate changes in parameters over time, while highlighting is utilized to demonstrate the load on specific components of the crane, such as the jib or horse-head jib. The load color changes from blue to red. In this way, the visualization of the mathematical model data helps to monitor the state of the crane components at each moment and analyze their positions, identifying the worst ones in terms of the load. In order to ensure the veracity and precision of the data, the application incorporates an interpolation tool, which is integrated into the system.

In fact, the application employs virtual reality to create a digital twin of a portal crane, which enables users to examine the patterns of its operation across a range of input parameter combinations. These include the configuration of crane components, the outreach and the weight of the cargo. Furthermore, the digital twin of the crane is capable of performing additional functions in the future due to the mathematical model's capabilities and the flexibility of the visualization system.

The software is designed to be used on multiple platforms. Two distinct versions of the software have been developed: one for use with a VR kit (VR headset and manipulators) and one for conventional personal computers with standard input devices (keyboard and mouse).

Technologies

| 3D development environment | Blender, Substance 3D Painter, Marmoset Toolbag |

| Software development environment | Unity, Visual Studio, JetBrains Rider |

| VR-kits | HTC VIVE PRO, Oculus Rift S и другие гарнитуры, совместимые с OpenXR |

| Programming languages and frameworks | С# |

Partners

- Gazprom PJSC

- Higher School of Transport of the Institute of Metallurgy, Mechanical Engineering, and Transport of SPbPU

Project Team

- Project manager: M.V. Bolsunovskaya, Head of the Industrial Systems for Streaming Data Processing Laboratory at SPbPU

- Consultant: A.A. Grachev, Ph.D., Director of the Higher School of Transport of the Institute of Metallurgy, Mechanical Engineering, and Transport of SPbPU

- Mathematical model developer: S.V. Nikitin, Ph.D., Associate Professor, Higher School of Transport of the Institute of Metallurgy, Mechanical Engineering, and Transport of SPbPU