Virtual booths for “Health and Safety” lab sessions

A set of digital hardware models for measuring noise factor, indoor climate, LUX level, concentration of pollutants in the industrial site.

Task

Students are given an opportunity to apply their knowledge in practice on their own via VR-technology that transfers them in a real environment of the industrial premises with its dangerous and harmful factors. Virtual space significantly increases the effectiveness of the educational process by providing an opportunity to analyze in detail the actions of the student during lab session

Within the Education Quality Improvement and Personnel Training Programme (2021-2022) for PJSC Gazprom/Peter the Great St.Petersburg Polytechnic University (SPbPU), personnel of the Industrial Systems for Streaming Data Processing Laboratory, NTI Center, SPbPU with the close involvement of the university's target units created three virtual laboratories delivering interactive experience.

Virtual space for the “Health and Safety” lab sessions is one of them.

Solution

The laboratory is a set of virtual hardware for measuring a noise factor, indoor climate, LUX level in the working room, and concentration of pollutants, influencing the environment in the industrial site exemplified by a compressor station.

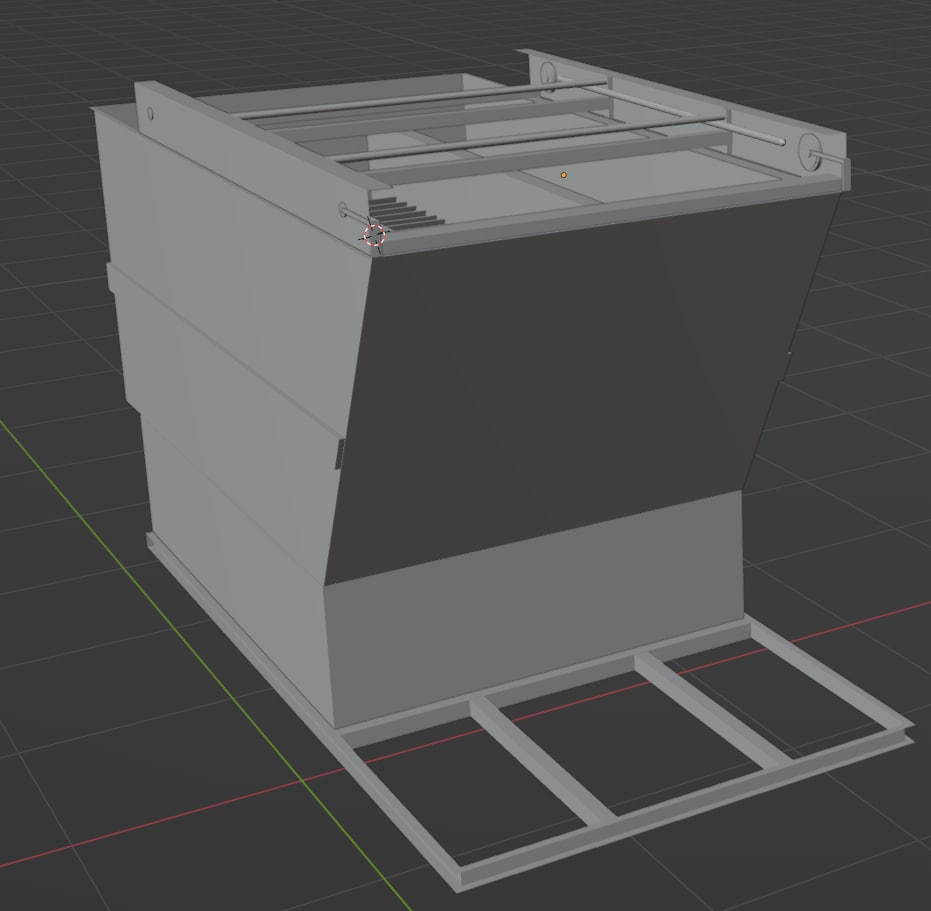

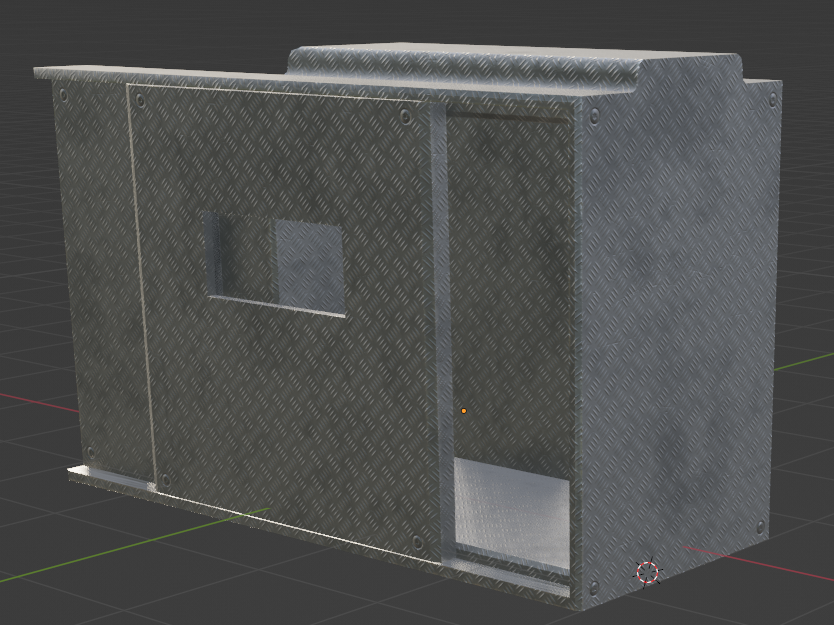

The project is based on the Unity3D real-time development platform. In the first stage, the equipment for lab sessions, including luxmeter, sound level meter, flotation unit, meteoscope, and various soundproofing covers, was digitized. A control desk was also designed during the first stage. Next, with the help of the Higher School of Technosphere Safety specialists, a simplified mathematical model was developed in order to emulate the operation of measuring devices in the VR-space. Interactive controls were attached to the resulting 3D models.

Then, we developed virtual scenarios of working with different types of equipment. Users receive auto-generated reports and protocols during the final stage of working with the program.

For instance, during a virtual lab session on the photic environment, the user (student) needs to do the following:

- Enter the room in which the emergency lighting is on;

- Switch on the light;

- Check the ventilators' stroboscopic effect;

- Measure the illuminance and percent flicker at given points of the shopfloor;

- According to the measurement results, it is necessary to determine which parameters of the quality of lighting in the compressor room do not meet the standards;

- Choose one of the options for the lighting system of the room, the colours of the walls, which will improve the quality of lighting;

- Re-measure parameters at given points in the room;

- Finish the work;

- Check and supplement the auto-generated report.

The program works via PC or VR kit. HTC VIVE PRO, Oculus Rift S, and other Steam VR-compatible headsets are required to utilize VR mode.

Technologies

| 3D development environment: | Blender, Substance 3D Painter, Marmoset Toolbag |

| Software engineering environment: | Unity, Visual Studio, JetBrains Rider, SteamVR |

| Software programming languages: | C# |

| Architecture: | x64 |

| OS: | Windows 10/11 |

Intellectual Property

Project team

Project Manager: M.V. Bolsunovskaya, Head of the Industrial Systems for Streaming Data Processing Laboratory, NTI Center, SPbPU.

Team Lead: A. A. Kuzmichev, Chief Project Engineer of the Industrial Systems for Streaming Data Processing Laboratory, NTI Center, SPbPU.