AI-based algorithms and software for creating digital models of industrial and socioeconomic systems

The development of a tool base for digital modeling based on artificial intelligence technologies.

Task

The use of digital modeling as a tool for describing or predicting the behavior (descriptive or prescriptive analytics) of socioeconomic and industrial systems provides formalization of the processes of systems functioning for further analysis, prediction, and selection of management measures.

The replacement of the original system with a digital model enables the investigation of the system's behavior in response to a range of external and internal influences. The reduction of determinism in systems results in a notable increase in the complexity of analytical decision-making. Consequently, computational methods, and in particular digital modeling, represent the optimal alternative.

The process of developing and researching digital models of industrial systems encompasses a number of stages that are characterized by a high degree of labor intensity. These stages include the preprocessing and quality assessment of input data, calibration, model quality assessment, flow experiments, and the analysis and visualization of results.

The objective of this project was to develop a platform solution that automates the most time-consuming and routine stages of digital model development. The implementation of process automation will be achieved through the use of artificial intelligence technologies, which have been trained on the expertise of researchers specializing in digital modeling.

The digital modeling platform with AI technologies will facilitate the development of digital models of industrial and socioeconomic systems at all stages of the lifecycle. The software will be capable of functioning in both remote and multi-user modes. The developed software will be made available for use by high-tech industry companies and regional executive authorities under license.

Solution

During the initial phase of the project (2023), a prototype of a configurable platform for digital modeling of industrial and socioeconomic systems based on artificial intelligence technologies was developed.

To date, the following software components have been developed, incorporated into the prototype, and tested:

- Input data preprocessing and quality assessment module employed in the digital modeling of industrial and socioeconomic systems, which is used to prepare (including preprocessing and quality assessment) input data for subsequent use in digital models.

The software tool analyzes data for blank values, outliers, noise, and duplicates, performs data type and unit consistency checks, and corrects data according to user-defined rules. The module reduces the labor intensity of input data preprocessing and quality assessment by at least 90%. It eliminates the probability of not detecting inconsistencies in the input data sets and takes into account the peculiarities inherent in the data accumulated in the process of functioning of industrial and socioeconomic systems. These include their formats, structures, and volumes.

- Algorithms and software tools for hybrid digital modeling of industrial and socioeconomic systems, which allow combining different approaches and modeling tools in order to create a set of connected multidimensional models of one industrial or socioeconomic system.

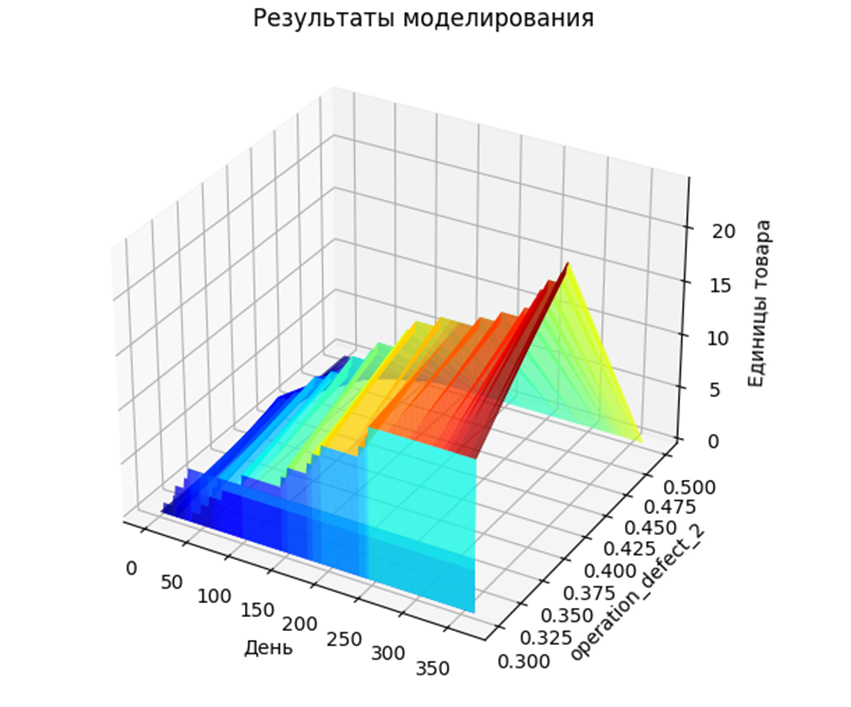

The module is designed to facilitate the integration of disparate approaches and modeling tools in order to generate a set of interrelated multidimensional models of a single industrial or socioeconomic system. It can be employed to execute multiple digital models implemented in the Python programming language in parallel in a customized manner. The module supports configurations of system dynamics models, agent-based models, discrete event models, and hybrid models. The model allows the user to run models with fixed or interval parameter values, adjust parameter values, and visualize experimental results. The results of the experimental process can be visualized in tabular format, as 2D and 3D graphs, or as a heat map. The user interface enables the user to conduct experiments and set values for model parameters.

- The aim of this module is to verify and validate the results of digital modeling of industrial and socioeconomic systems, with a view to a configurable platform for evaluating the applicability of the developed models.

The module assesses the accuracy of digital models of industrial and socioeconomic systems relative to reference data, employing metrics such as mean squared error (MSE), mean absolute error (MAE), mean absolute percentage error (MAPE), R2, dispersion, and area difference. The software tool allows checking the stability of digital models of industrial and socioeconomic systems through artificial fluctuations of the original data using scatter metrics such as standard deviation (SD), dispersion (absolute and relative), and spread (absolute and interquartile range).

The module is also capable of visualizing the sensitivity of digital models of industrial and socioeconomic systems. The module employs verification and validation methods that are typical for models of industrial and socioeconomic systems, namely accuracy, stability, and sensitivity analysis. The module is versatile with respect to the type of digital models and works with system dynamics, discrete-event, agent-based, and hybrid models of varying complexity. The implementation of the module has led to a significant reduction in the labor-intensive verification and validation processes for digital models of industrial and socioeconomic systems by at least 50%.

- Video data compression software based on neural network technologies.

The module has been designed for the recompression of the input video stream with a high level of compression while ensuring the preservation of features essential for machine analytics. The software can be used for transcoding and storing video data in intelligent video surveillance systems where a high degree of compression is required while maintaining the high accuracy of machine video analytics.

- Software solution for heterogeneous data preprocessing, designed to enhance the performance of neural network algorithms in the textile industry.

The module has been designed for the preprocessing of textile canvas video data in order to facilitate the efficient analysis of fabric defects by means of neural network algorithms. The module can be employed for the parallel processing of frame streams originating from disparate sources, utilizing trained neural network models of the YOLO architecture. Furthermore, it can be used for the subsequent synchronization of the obtained data and the formation of a common defect map.

The model is capable of executing NS models on both the central and graphics processors, if available, to enhance processing speed. It can also accommodate a variable number of cameras or other sources of frames, and it can handle both color and monochrome images of any size.

Technologies

| Programme languages and frameworks | Python, numpy, PyQt5, pandas, matplotlib, scipy |

| OS | Windows 10 |

| CVS | Git |

| IDE | PyCharm |

Contractor

Digital Modeling of Industrial Systems Laboratory, SPbPUPartners

- Roku LLC

- Huawei Technologies Co. Ltd.

- Engineering Centre of Textile and Light Industry

- Gazprom Neft PJSC