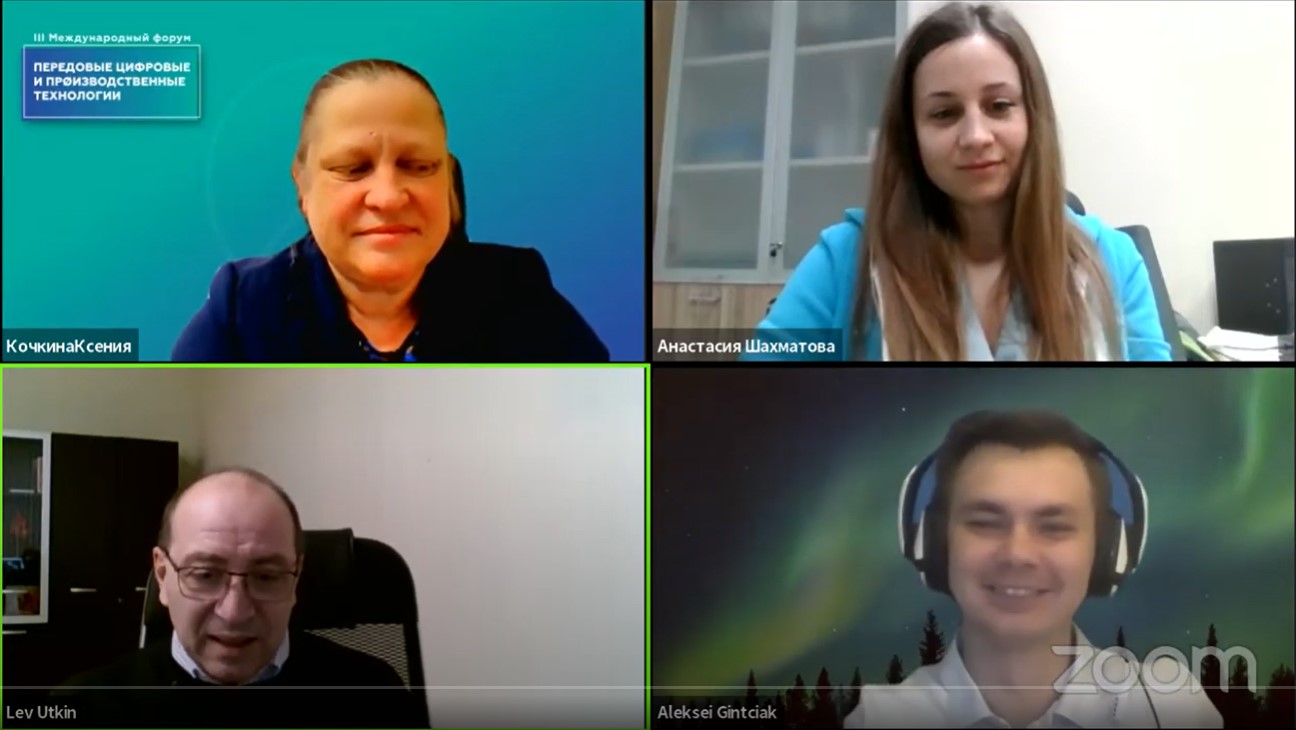

Third International Forum “Advanced Digital and Manufacturing Technologies”: Workshop on Artificial Intelligence.

As part of the business program of the Third International Forum “Advanced Digital and Manufacturing Technologies”, the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center arranged the Workshop on Artificial Intelligence. The Forum was organized by Peter the Great St. Petersburg Polytechnic University (SPbPU) and its structural divisions, which are the […]

As part of the business program of the Third International Forum “Advanced Digital and Manufacturing Technologies”, the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center arranged the Workshop on Artificial Intelligence.

The Forum was organized by Peter the Great St. Petersburg Polytechnic University (SPbPU) and its structural divisions, which are the World-Class Research Center for Advanced Digital Technologies of SPbPU (SPbPU WCRC) and the National Technological Initiative for Advanced Manufacturing Technologies of SPbPU (SPbPU NTI Center). The Forum was included in the Year of Science and Technology event program and supported by the Ministry of Science and Higher Education of the Russian Federation within the “Science and Universities” national project.

Representatives of the ISSDP Laboratory’s partners (companies and universities using AI algorithms and technologies in their research and development) were invited to participate in the Workshop on Artificial Intelligence. The Workshop reports discussed industry solutions using AI for the textile and manufacturing industries, the transport industry, video surveillance and security, healthcare, etc.

Representatives of SPbPU WCRC for Advanced Digital Technologies presented their developments in the field of machine learning and reviewed the implemented projects and technological opportunities for their development.

The Workshop moderator was Marina V. Bolsunovskaya, Ph.D., Associate Professor, Head of the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center.

Speakers:

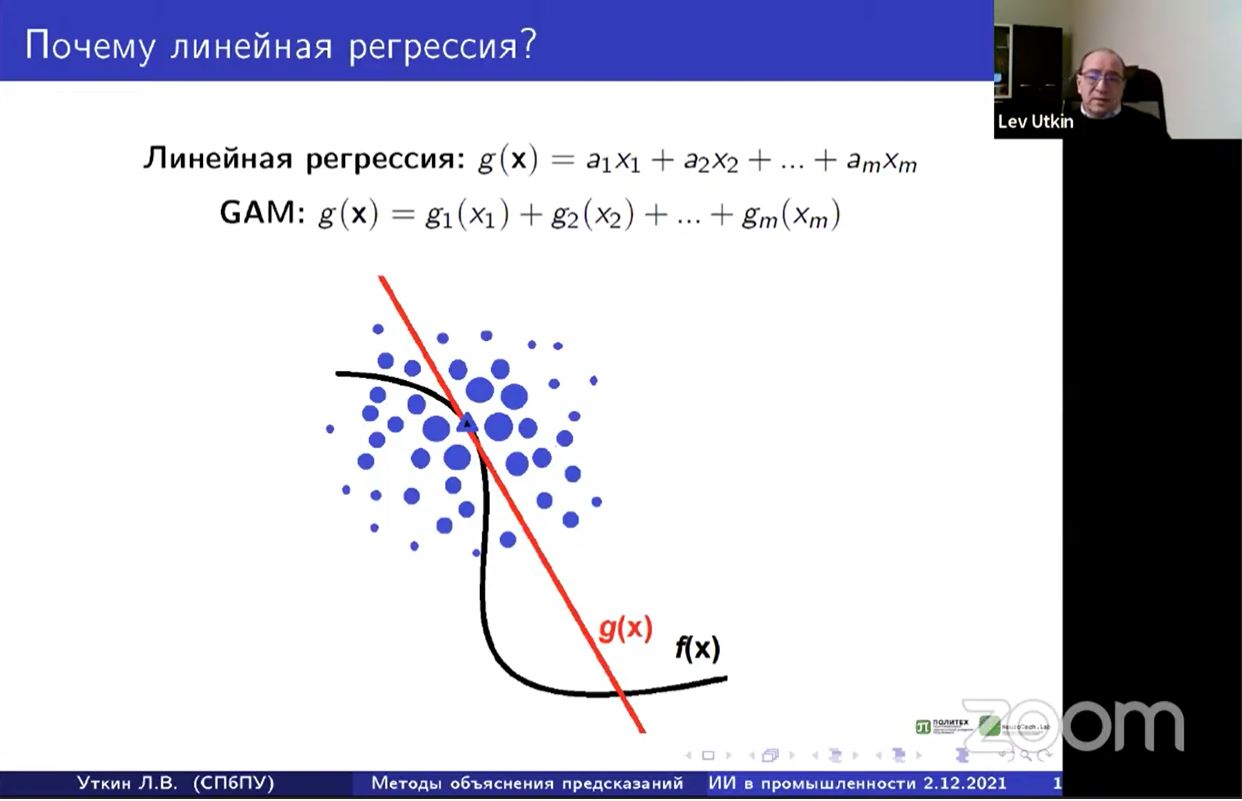

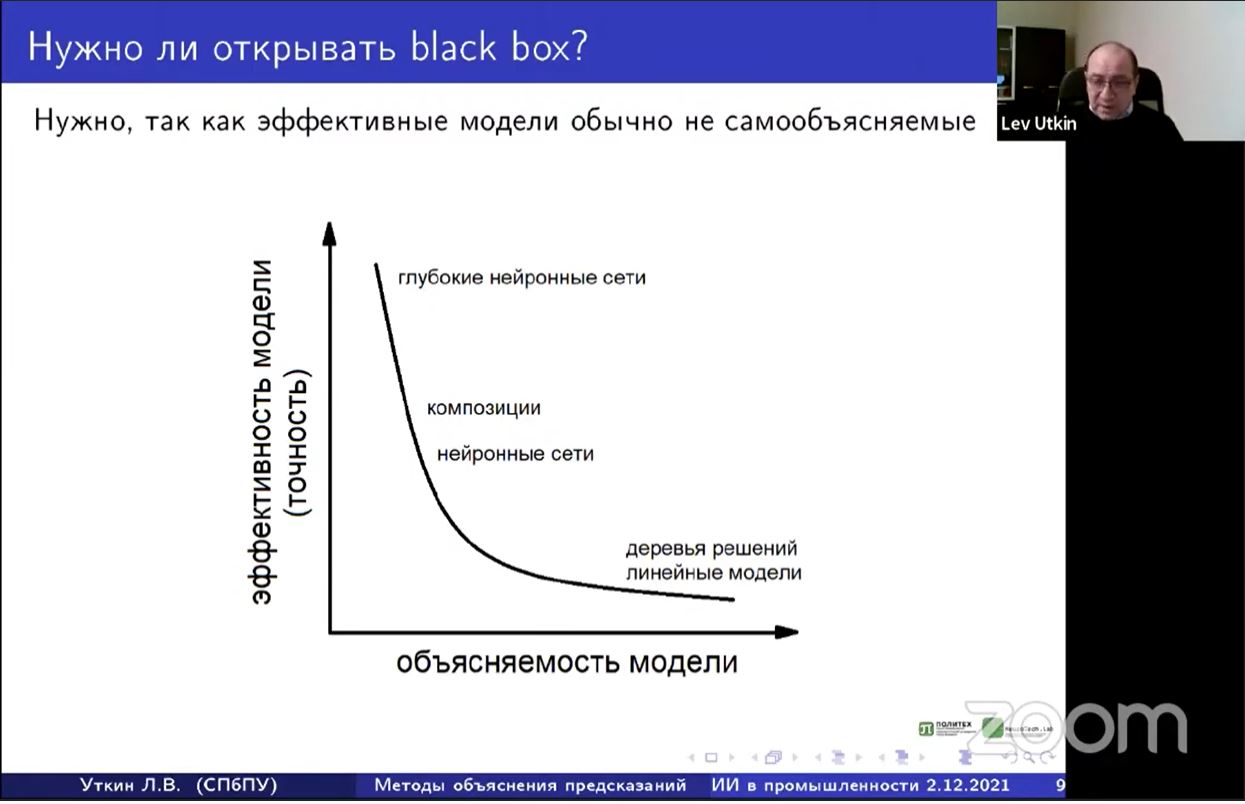

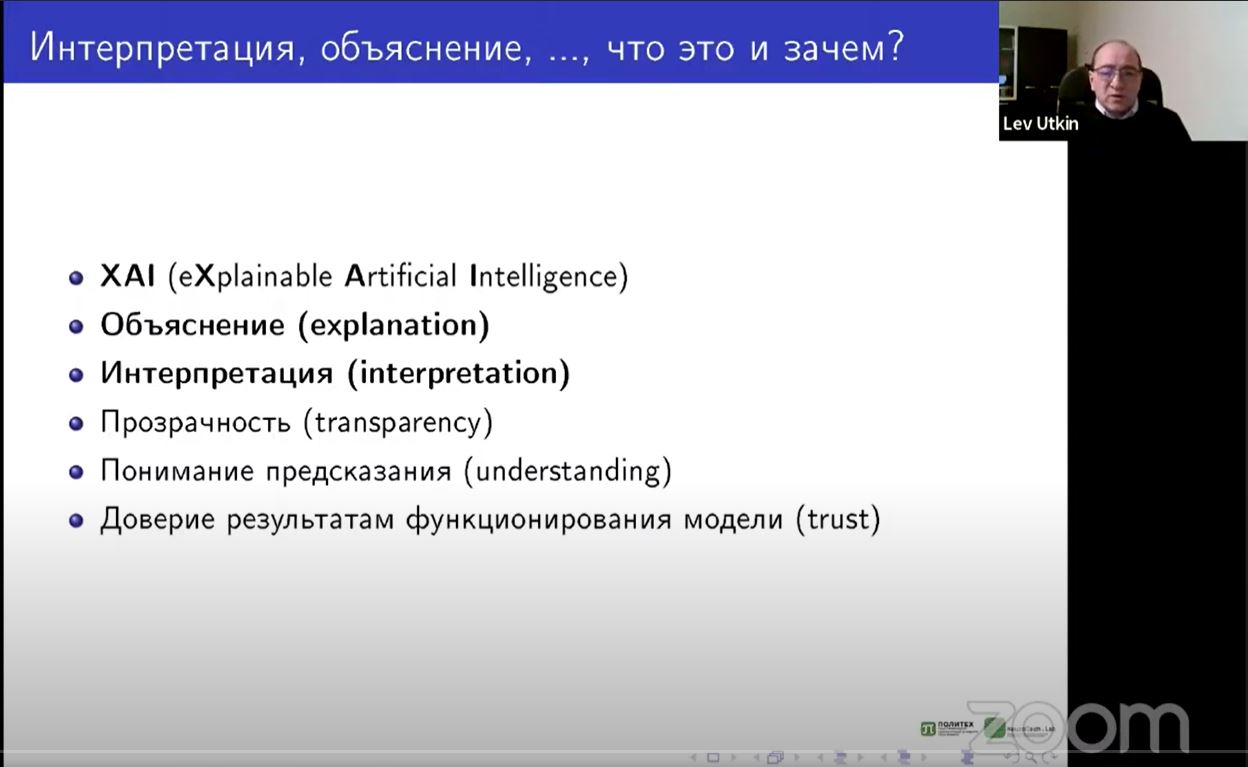

- Lev V. Utkin, Doctor of Technical Sciences, Professor of the Graduate School for Artificial Intelligence of ICST SPbPU, Head of the Neural Network Technologies and Artificial Intelligence Research Laboratory. Methods for explaining predictions of machine learning models.

- Andrey V. Konstantinov, Engineer of the Supercomputer Technologies and Machine Learning Research Laboratory of SPbPU. Multivariate learning based on multiple attention models.

- Ilya M. Afanasyev, Team Leader of the Media Algorithms team of the St. Petersburg Research Center Huawei Technologies Co.AI algorithms and technologies application in transport systems digital models.

- Denis A. Miroshnichenko, Senior Researcher at the Research and Education Center of Ivanovo State Polytechnic University. AI application prospects in the textile industry. Development of a neural network for detecting fabric faults in the textile industry.

- Anastasia M. Shakhmatova, Analyst of the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center. Data acquisition and preparation for the development of a hardware and software complex for detecting and classifying fabric faults using neural network technologies.

- Georgy R. Zagorodny, Programmer of the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center. Development of an automatic image exposure correction system from an industrial camera to compensate for various lighting conditions.

- Alexander V. Stakhiev, Programmer of the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center. Development of a system for automatic stitching of images from several industrial cameras.

- Alina V. Cherkas, Research Engineer of the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center; Stanislav P. Urazov, Medical Methodologist of the organizational and methodological department for Medical Rehabilitation, St. Petersburg State Budgetary Healthcare Institution “City Hospital No. 40”. Development of a classifier for the new coronavirus infection (COVID-19) severity prediction.

- Alexei M. Gintciak, Head of the Digital Modeling of Industrial Systems Laboratory of the SPbPU NTI Center, Researcher at the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center. Key approaches to industrial systems digital modelling.

Lev V. Utkin opened the Workshop.

In his report “Methods for explaining predictions of machine learning models”, Lev Utkin spoke about the key research areas in the field of explicable artificial intelligence. Most of the modern AI systems are a “black box” that does not provide justifications for their own decisions. The described situation does not allow to fully rely on such decisions and predictions of AI systems. An alternative approach may be to create self-explanatory models, which usually have less predictive power compared to other models. Finding a balance between the model explicability and effectiveness is an urgent problem that can be solved locally depending on the task assigned to the developers of a particular model,” the speaker noted.

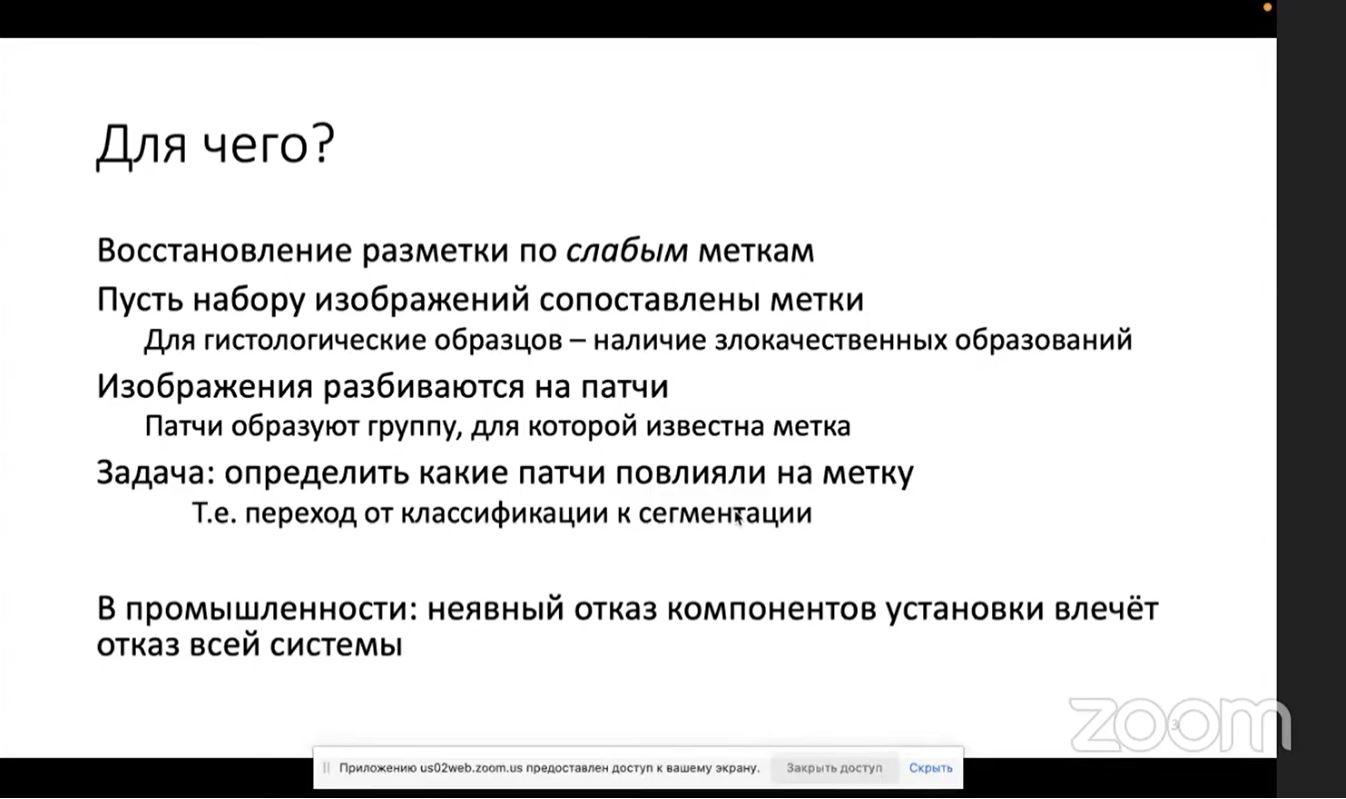

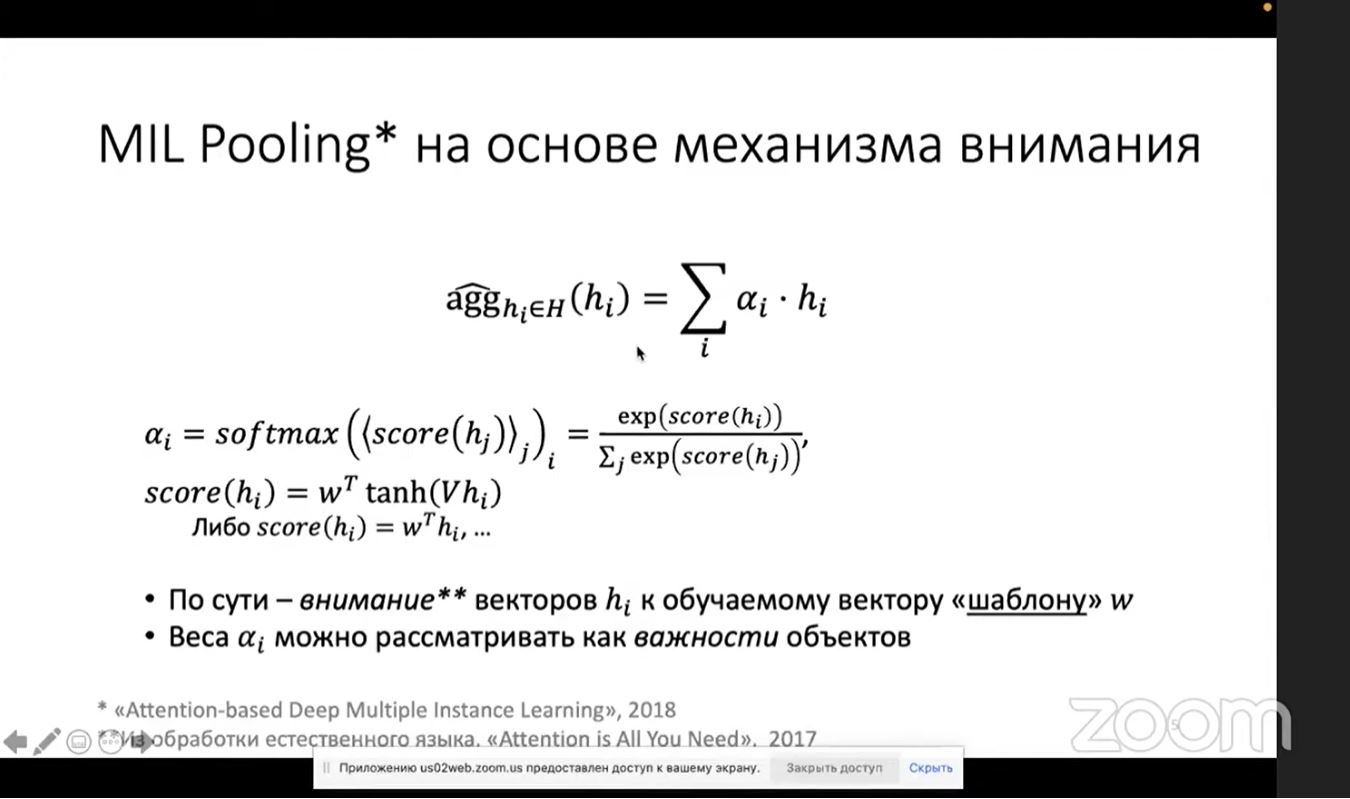

Lev Utkin’s report thesis statements were revealed in greater detail in the report of Andrey V. Konstantinov, Engineer of the Supercomputer Technologies and Machine Learning Laboratory of SPbPU. The report dealed with multivariate learning based on multiple attention models. Andrey Konstantinov noted that the multivariate learning objective is set based on designing classifiers both at the group level and at the object level for available objects groups and their corresponding deliberately unknown labels. This task is relevant for the restoration of markup by weak labels, which can be used in AI models while transiting from classification to segmentation. The multiple use of the attention mechanism makes it possible to solve new, more complex tasks of multivariate learning,” the expert believes.

The report of Ilya M. Afanasyev, Team Leader of the Media Algorithms team of the St. Petersburg Research Center Huawei Technologies Co., discussed current issues of using AI algorithms and technologies for monitoring transport systems in urban environments, which the Multimedia Algorithms team of the St. Petersburg Research Center Huawei Technologies Co. faced.

Transport system monitoring current issues are associated with the detection, classification, localization, and tracking of a large number of diverse road users such as motor vehicles of various types, motorcycles, bicycles, pedestrians, etc. Algorithms and AI technologies applied for data sets, both for individual cameras and for multi-camera systems, are widely used for monitoring. In this case, there are following ways of AI models application: for parking lots, intersections, highways, etc. Solutions must be robust for different seasons, time of day, weather conditions, etc. In addition, real difficulties may arise with an increase in the size of roads and intersections, as well as with a rapid and substantial increase in the road users number during traffic jams.

In the following four reports, various aspects of the project, which is being conducted by the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center in cooperation with the Ivanovo State Polytechnic University, were highlighted.

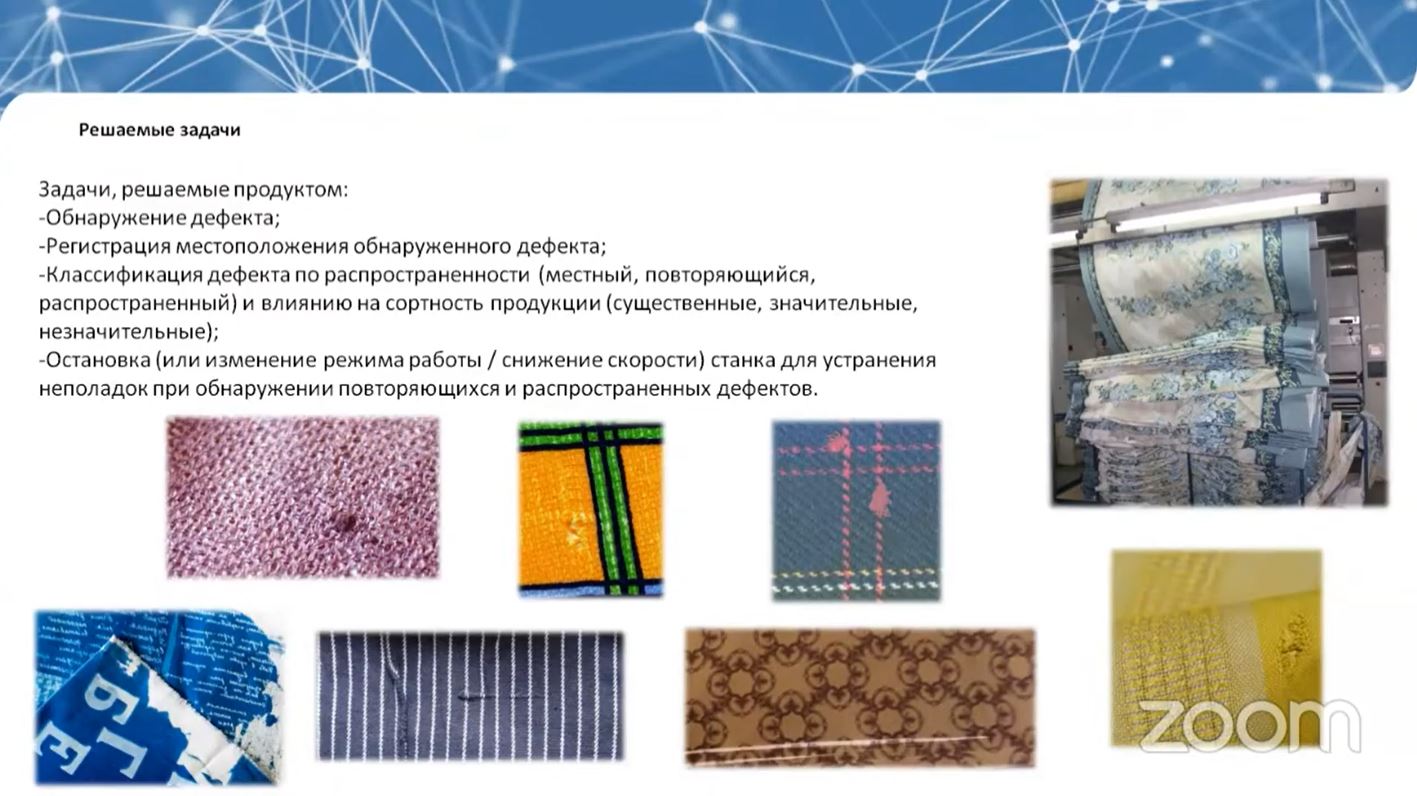

The project on the development of neural networks and a hardware and software complex for detecting fabric faults on large-width moving roll materials with various types of surface design was presented in the report of Denis A. Miroshnichenko, Senior Researcher at the Research and Education Center of Ivanovo State Polytechnic University (ISPU). The speaker described the essence of the project, listed the main technical features of the upcoming solution, and emphasized the relevance of the hardware and software complex for woven fabric faults automatic detection and recognition under development for textile manufacturing digitalization.

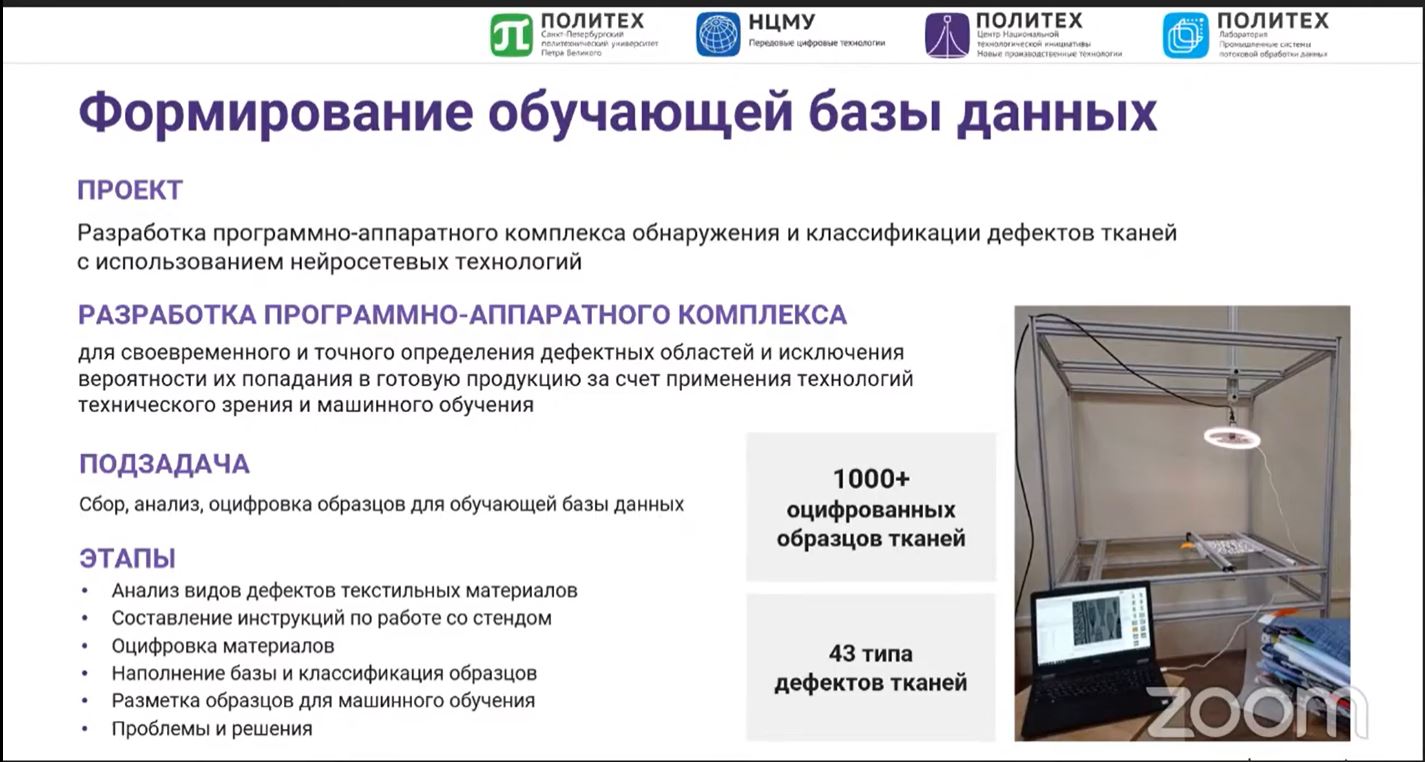

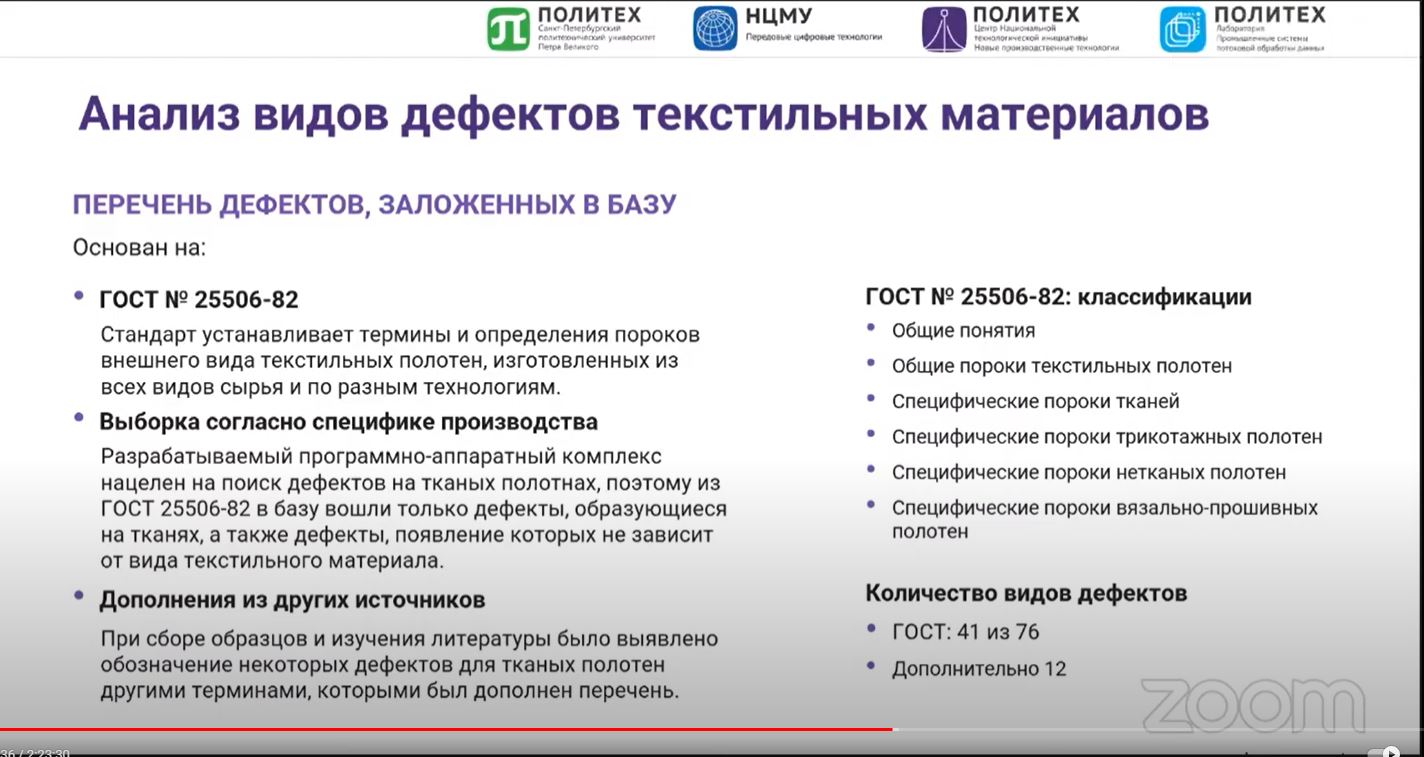

Anastasia M. Shakhmatova, Analyst at the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center and a project team member, spoke about the preparation of a fabric faults database including data acquisition, analysis, digitization of defect samples for training neural networks. To date, more than 1,000 samples have been digitized and 43 types of fabric faults have been identified.

This most important preparatory stage included the analysis of defects types, elaboration of the testing device operation instructions, digitizing materials, making up the database and classifying samples, marking samples for machine learning and solving emerging problems, for example, the moire problem (distortion in the form of stripes of different size and direction with a shade of yellow and green that appeared in video images when shooting monochrome materials).

Then the programmers of the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center showed the technical aspects of working with video images.

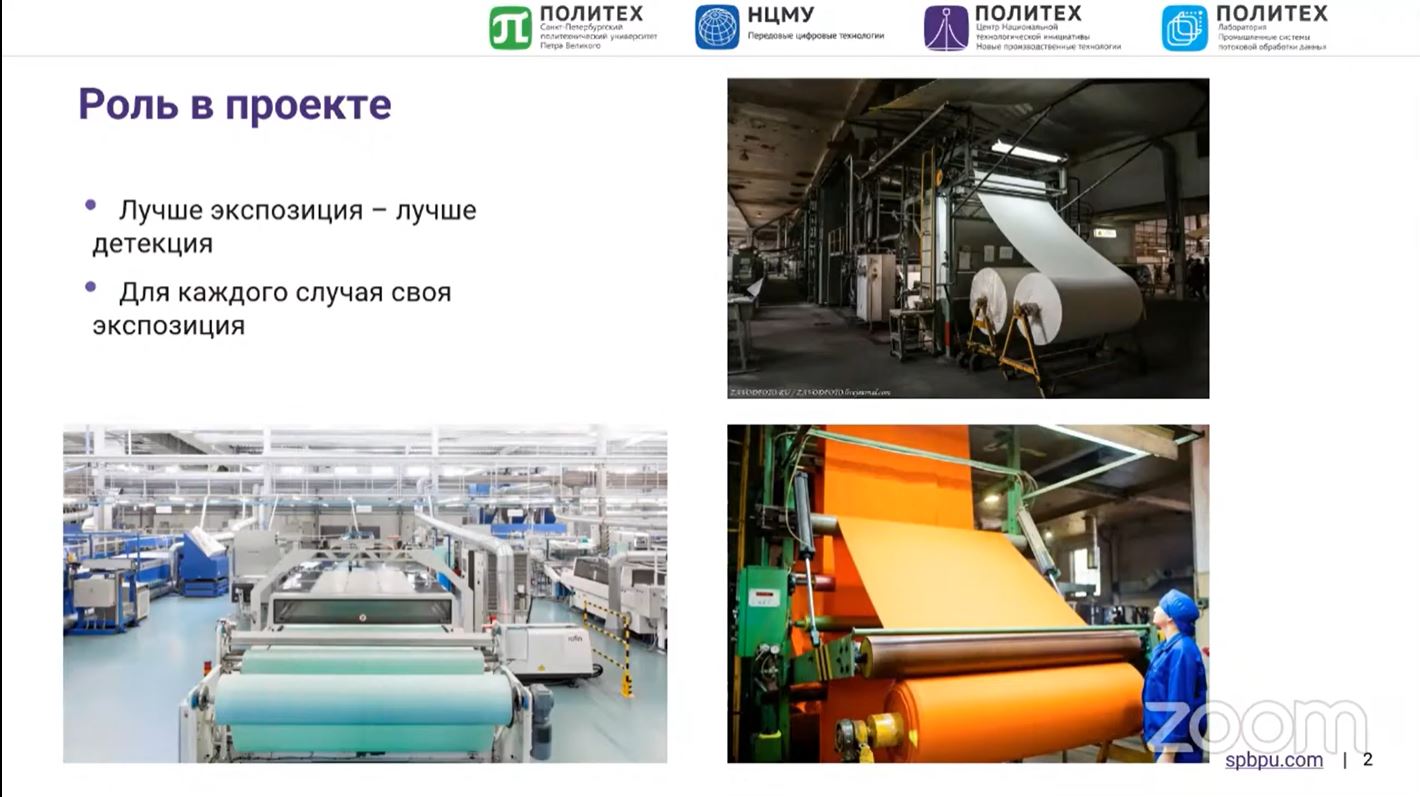

Georgy R. Zagorodny spoke about the development of an industrial camera automatic image exposure correction system to compensate for various lighting conditions. In this project, it is crucial to get the highest quality image from the camera, since the more information there is in the frame, the better the detection neural network will work. A software has been developed that changes the camera parameters analyzing the histogram of the image. The method developed has a good operating speed and high stability even with a sudden change in the fabric color. In further research, it is planned to compare the elaborated algorithm with modern developments in this area.

Alexander V. Stakhiev presented a system for automatically stitching images from several industrial cameras. When searching for fabric faults, this technique helps to ensure high-quality images on a canvas of great length, which directly affects the defect detection accuracy. As a result of using the classical approach based on the search for key points, obtaining high accuracy on synthetic data was gained. However, this approach turned out to be not stable enough when working with real data, so the project team intends to explore other approaches, such as, for example, the use of optical flow and neural networks.

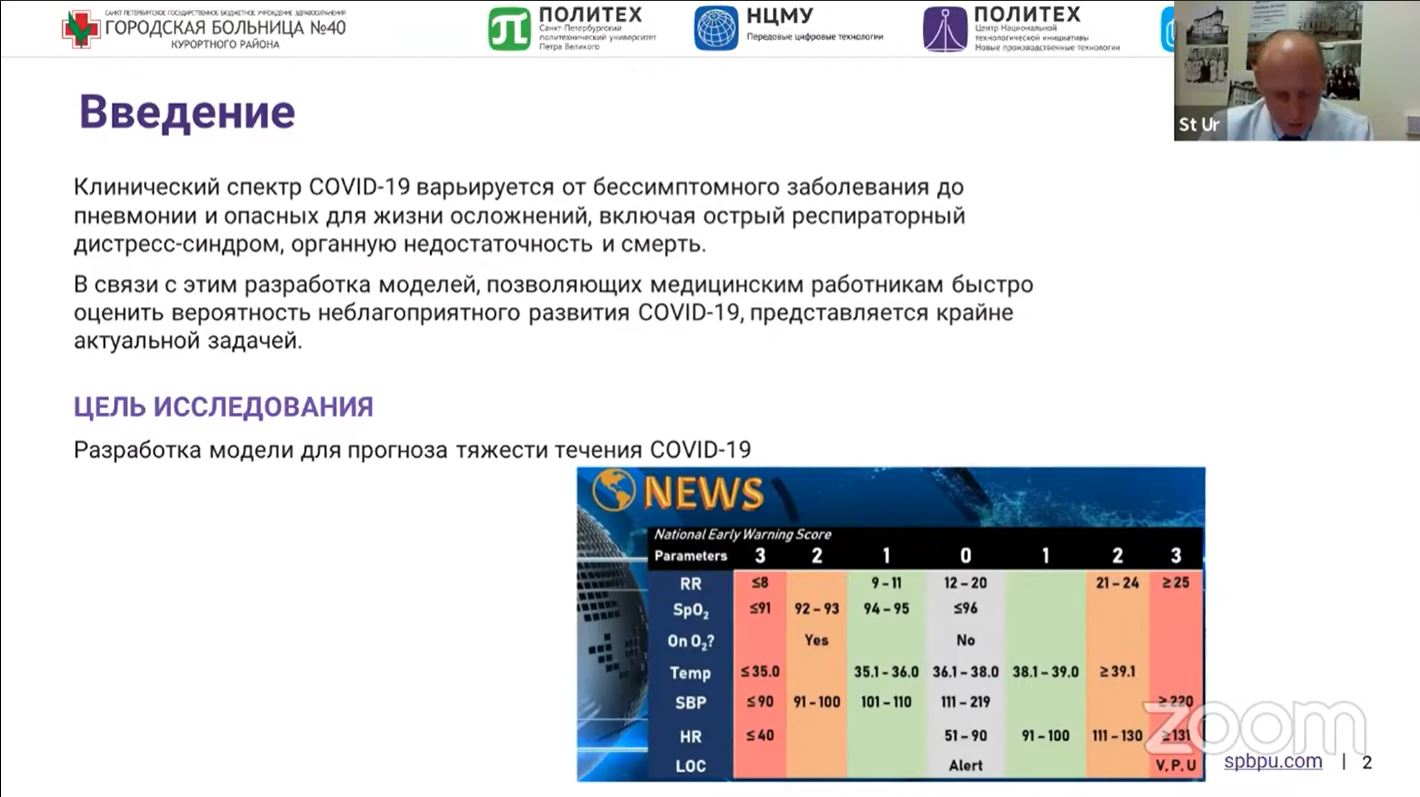

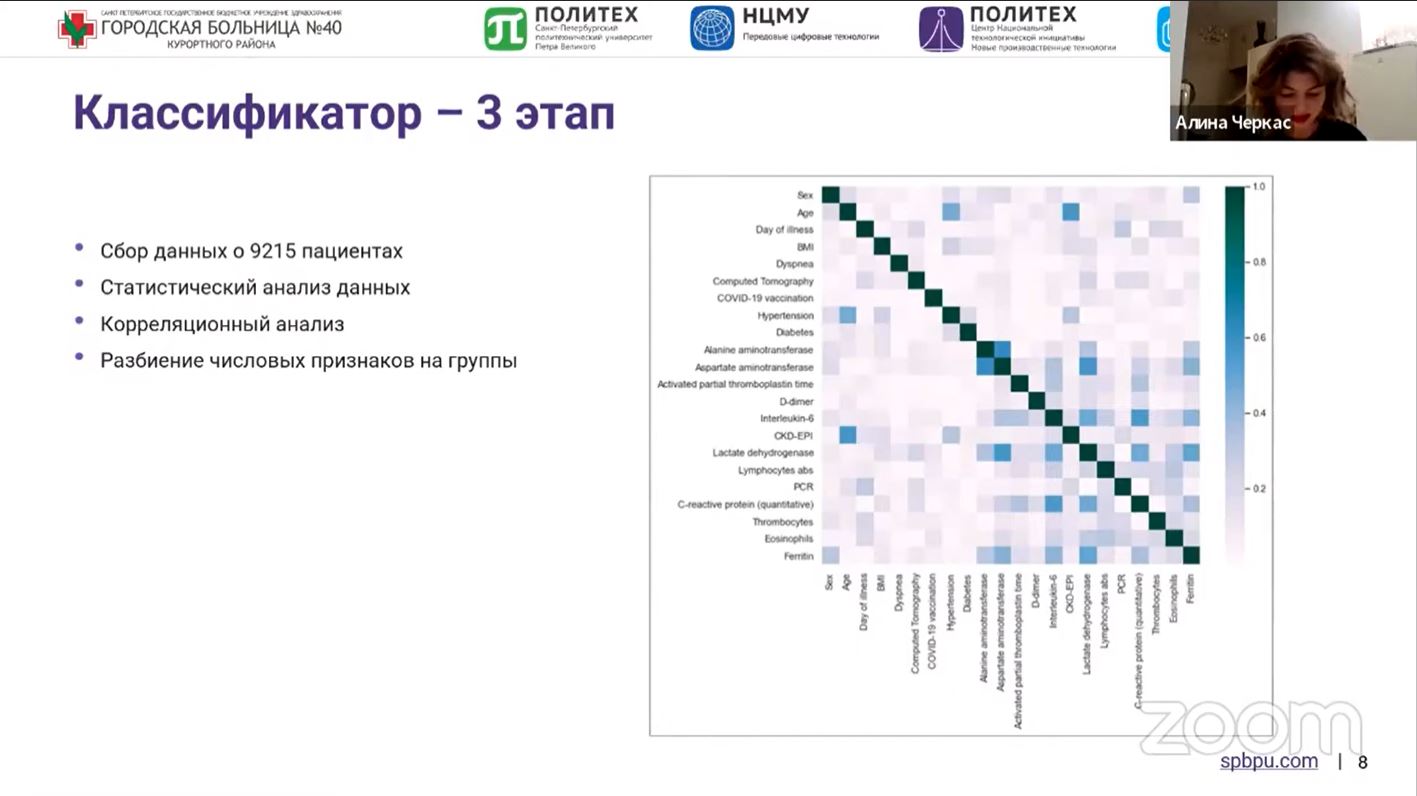

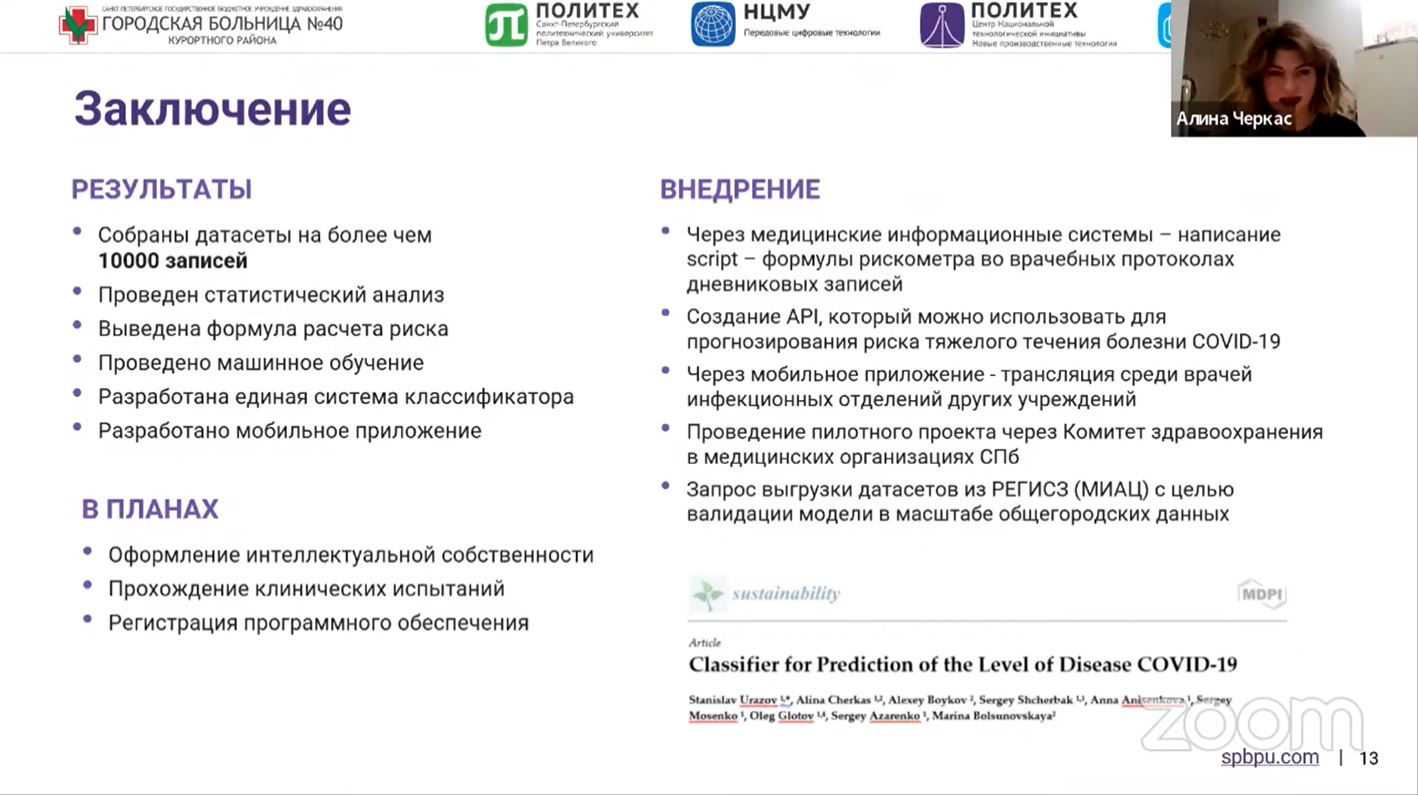

Stanislav P. Urazov, Medical Methodologist of the organizational and methodological department for Medical Rehabilitation, St. Petersburg State Budgetary Healthcare Institution “City Hospital No. 40”., and Alina V. Cherkas Research Engineer of the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center and Specialist in the Research Department of Innovative and Conversion Programs of St. Petersburg State Budgetary Healthcare Institution “City Hospital No. 40”, described the case of the AI technologies application in healthcare in their joint report “Classifier of the new coronavirus infection (COVID-19) severity prediction development”.

“The introduction of a unified state healthcare system is only gaining momentum, the completion of the introduction of unified standards and clinical recommendations in medicine began this year and will last until 2024,” Alina Cherkas noted. “The structure of medical information is extremely heterogeneous, so many attempts to develop software algorithms using AI have not been successful. Nevertheless, we have set the goal of forming a forecast model on the most relevant topic to date, using the resources of the medical information system and the ability to automatically upload large amounts of data.“

The report presented the process of acquiring more than 10,000 data units on 117 clinical and laboratory indicators of patients with COVID-19 and their analysis, as well as training 19 machine learning models in two scenarios. The accuracy (AUC) of the main model trained using the Stochastic Gradient Descent algorithm was more than 90%.

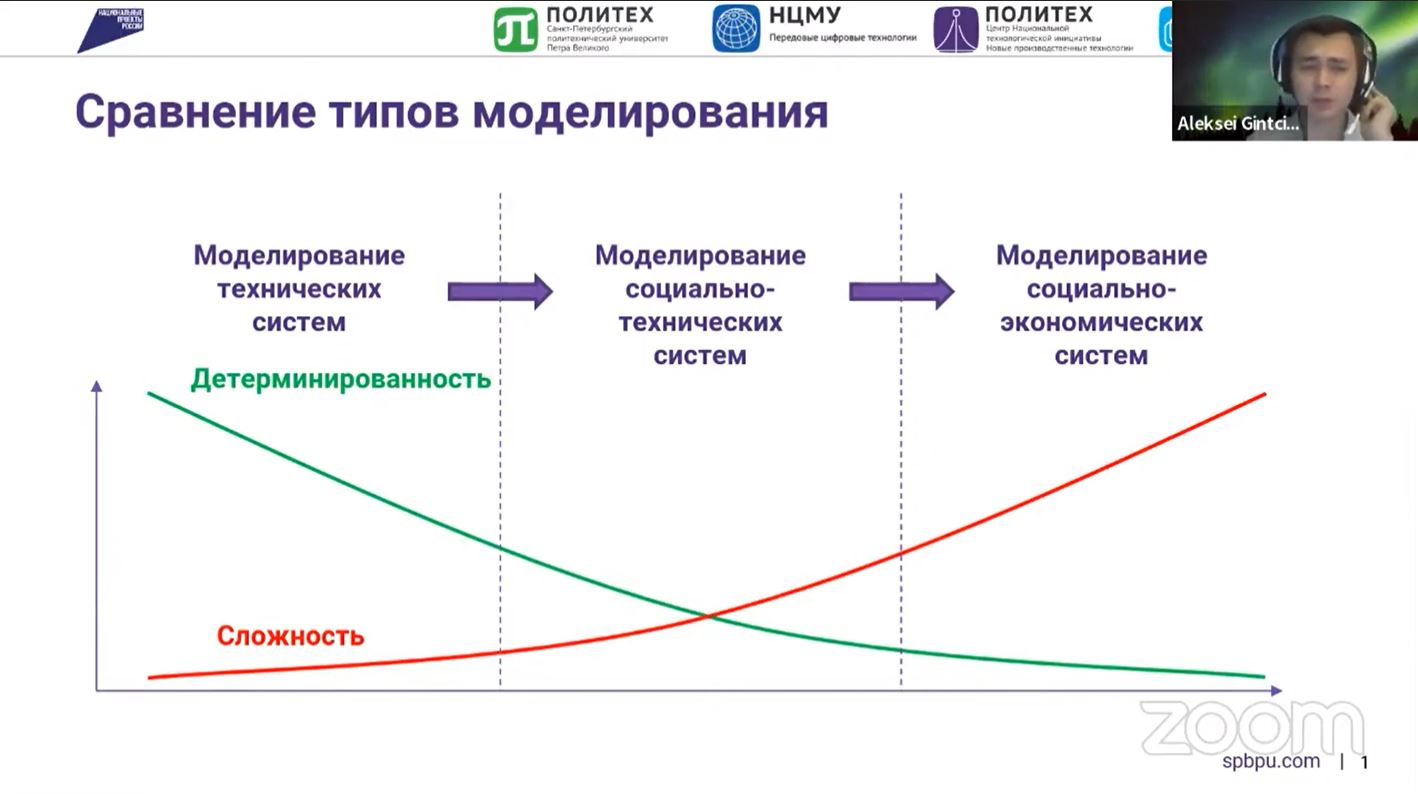

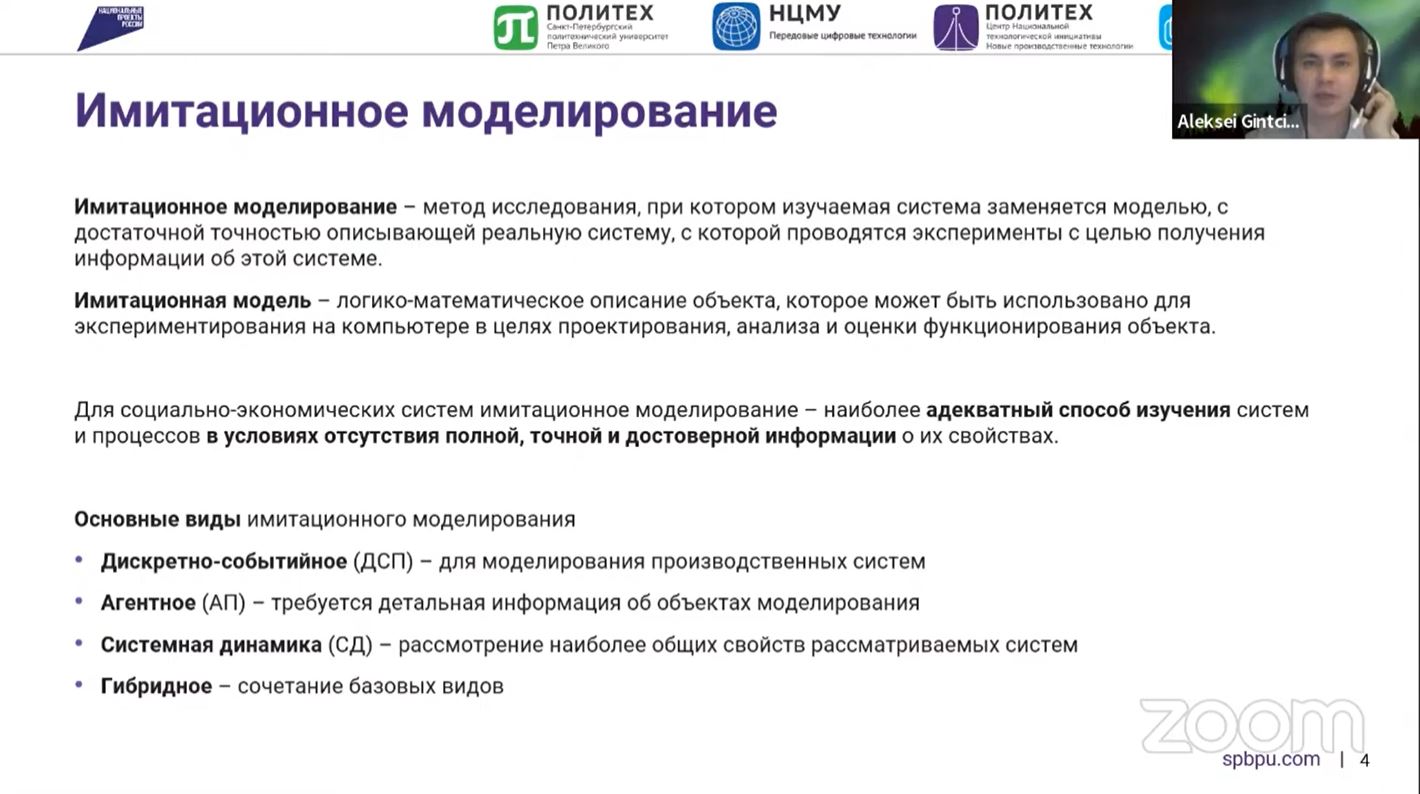

At the end of the Workshop, Alexei M. Gintciak, Head of the Digital Modeling of Industrial Systems Laboratory of the SPbPU NTI Center, Researcher at the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU NTI Center, delivered his report “Key approaches to industrial systems digital modeling.”

“The task of modeling socio-technical and socio-economic systems presents new challenges to researchers,” the speaker believes. “Manned systems have a fundamental complexity associated with the lack of determinism at the individual level.”

Alexei Gintciak noted that the solution to this issue can be a combination of traditional tools for modeling socio-economic systems with tools and approaches used in technical systems modeling, such as mathematical modeling and dynamic forecasting, interval approach, sensitivity analysis, calibration, verification, and validation.

“The use of these methods allows to solve the tasks of predictive and prescriptive analytics of the socio-technical and socio-economic systems functioning,” Alexei Gintciak believes.