Virtual compressors of an underground gas storage facility

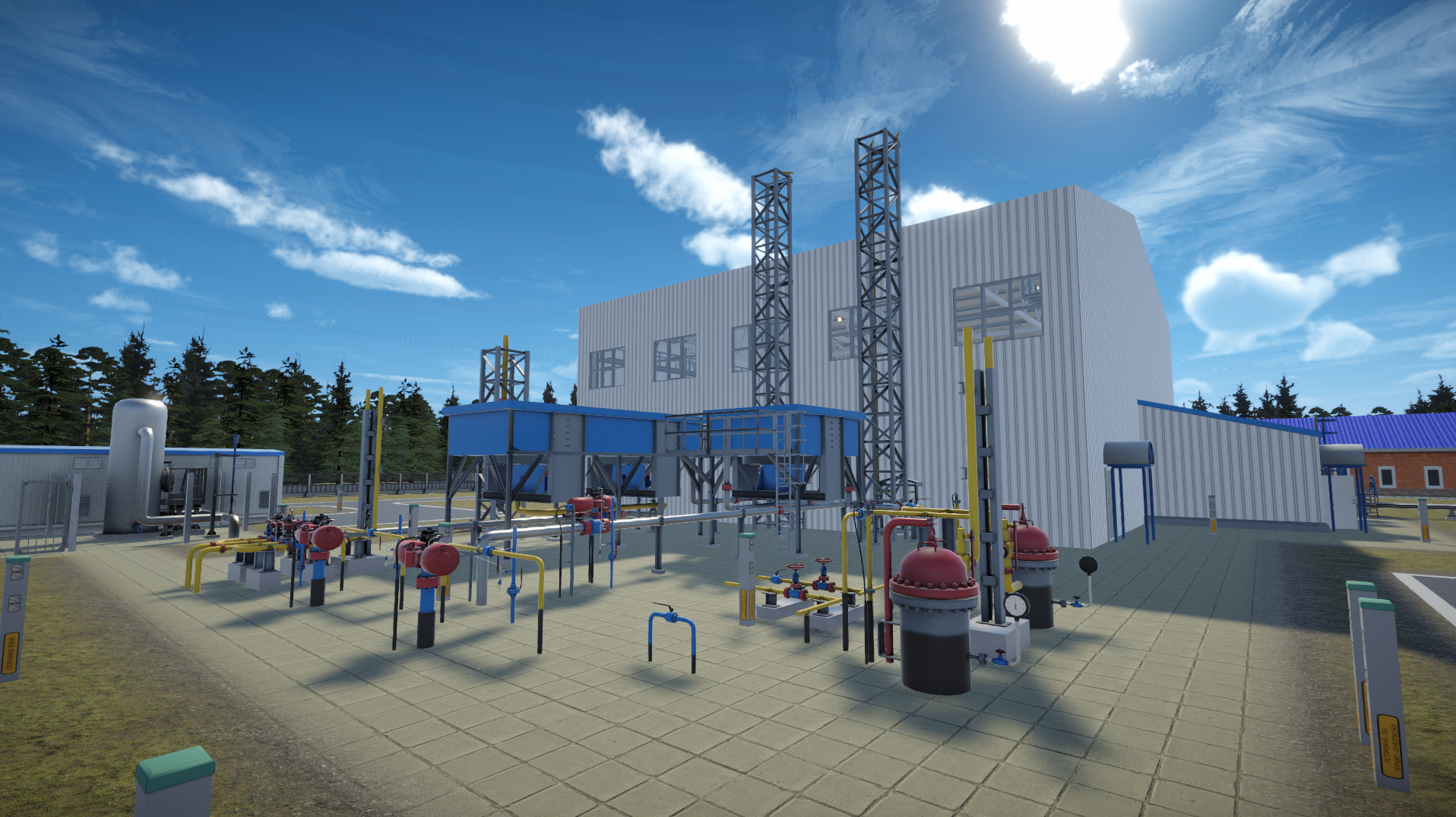

Virtual model of the compressors of an underground gas storage facility

Task

The task is to develop a VR training application for students of the Higher School of Power Engineering of the SPbPU Institute of Machinery, Materials, and Transport, with a focus on the following fields: 'Compressor, Vacuum, Refrigeration Technology, and Gas Transmission Systems' and 'Gas Turbine Units of Gas Compressor Stations'.

The objective of the application is to provide users with the knowledge and skills required to operate compressor stations at underground gas storage facilities in accordance with the duties and responsibilities of operators of actual underground gas storage facilities.

The utilization of interactive 3D models and scenarios of interaction with them enables students to undertake virtual maintenance and repair tasks whilst simultaneously developing an understanding of how to identify and respond to emergency situations.

The objective of the development is to equip students with the knowled

ge and skills required to maintain UGS compressor and auxiliary equipment, to diagnose and resolve operational issues, and to ensure the safety of personnel on site. It is imperative that users are able to make their own decisions regarding the extent to which equipment deviates from its normal operational state. In order to do so, they must be able to identify the potential dangers inherent in such situations and act with an understanding of the cause-and-effect relationship between their actions and the reaction of the equipment.

Solution

The virtual laboratory is a 3D model of an underground gas storage station, equipped with a set of interactive control tools and a series of training programmes designed to simulate real-world scenarios for users.

The model simulates the operation of compressor equipment in both normal and emergency modes. Users are trained in the maintenance and repair of equipment and are instructed in emergency procedures.

The lab session scenarios are based on the technological regulations, bypass routes, and algorithms of an operator's work at the Nevskoye Underground Gas Storage Facility of Gazprom UGS in St. Petersburg.

3D modeling

Three-dimensional models serve to reproduce the principal components and architectural structure of the UGS within a virtual environment. The models were developed on the basis of a real facility of Gazprom UGS, namely the Nevskoye Underground Gas Storage Facility named after Hero of Socialist Labour S.F. Barmin, which is located in the village of Kresttsy, Novgorod region. Nevskoye UGS provides gas injection into porous formations, its storage, and extraction. It ensures the reliable operation of the gas supply system in the North-West region by regulating the seasonal irregularity of gas consumption.

As the project focuses on the maintenance of gas pumping units (GPU) and systems related to the compression of natural gas and its injection into underground storage, the model of compressor workshop No. 3 is notably comprehensive. It is a building with engineering systems and three identical GPUs comprising a gas-fueled internal combustion engine and a two-stage reciprocating compressor.

A number of auxiliary systems have been modeled, including the air cooling unit (ACU) of the liquid cooling system of the internal combustion engine and piston compressor, the air cooling unit of gas, the air cooling unit of glycol and gas, the liquid cooling system of the engine and piston compressor, the block-container of the air compressor station, the fuel gas treatment system, the premises of the electric room and the compressor unit of starting air, the lubrication system of the internal combustion engine and piston compressor, the fire suppression system, and a number of other.

The developers undertook multiple site visits to the UGS, utilizing a range of materials, including drawings, schematics, an illustrated parts list, photographic and video materials, presentations, and text descriptions, to develop the models.

Scenarios

The VR application simulates the operation of the CNG filling station compressor equipment and auxiliary systems. A distinct software module has been developed for the purpose of facilitating virtual training sessions.

The scenarios of user actions in the system were developed by experts from the Higher School of Power Engineering of the Institute of Energy Engineering of SPbPU. These scenarios were developed on the basis of the relevant technological regulations, as well as the bypass routes and actions of CNG filling station operators.

The scenarios of lab sessions are designed to provide students with a comprehensive understanding of the duties and responsibilities associated with the role of a compressor unit operator, with a particular focus on the duties and responsibilities of a compressor station shift engineer.

Available scenarios:

- Regular bypass of GPU on standby (hot standby)

- GPU launch preparation;

- GPU launch;

- GPU loading;

- GPU maintenance during operation;

- GPU maintenance shutdown procedure;

- Shift personnel emergency actions;

- Maintenance of the GPU unit, auxiliary equipment, and shut-off valves.

Cross-platform compatibility

The software is designed to be used on multiple platforms. The project has been developed in two versions. One is designed for use with virtual reality tools, while the other, more lightweight version is intended for use with ordinary personal computers.

The VR hardware version provides a more immersive experience and offers a greater quantity of informative content; however, it necessitates a considerable amount of computer processing power.

The version designed for use with standard input devices (keyboard, mouse) has the advantage of conserving PC resources, as it does not require the rendering of two images simultaneously. The software is compatible with laptops of moderate processing power.

The system for user interaction with interactive objects is versatile and possesses logic that is independent of the platform.

Technologies

| 3D Development Environment | Blender, Substance 3D Painter, Marmoset Toolbag |

| Software Development Environment | Unity, Visual Studio, JetBrains Rider |

| VR-kits | HTC VIVE PRO, Oculus Rift S и другие гарнитуры, совместимые с OpenXR |

| Programming languages and frameworks | С# |

Key contributors

- Project manager: M.V. Bolsunovskaya, Head of the Industrial Systems for Streaming Data Processing Laboratory at SPbPU

- Consultant: A.A. Drozdov, Head of the ‘Research of Compressors, Pneumatic Systems, and Gas Compression and Processing Facilities’ research programme at the Higher School of Power Engineering of the SPbPU Institute of Energy

Partners

- Gazprom PJSC, Gazprom Transgaz Saint Petersburg LLC

- Higher School of Power Engineering of the Institute of Energy of SPbPU