Virtual compressors of a gas filling station

Interactive digital model of compressor and auxiliary equipment of a compressed natural gas filling station

Task

The task is to develop a VR training application for students of the Higher School of Power Engineering of the SPbPU Institute of Energy, with a focus on the following fields: 'Compressor, Vacuum, Refrigeration Technology, and Gas Transmission Systems' and 'Gas Turbine Units of Gas Compressor Stations'.

The objective of the development is to equip students with the knowledge and skills required to maintain CNG filling station compressors, to diagnose and resolve operational issues, and to ensure the safety of personnel on site. Virtual laboratory sessions will facilitate students' comprehension of the processes occurring in the CNG filling station equipment.

For example, they will be able to make independent assessments of the extent to which equipment deviates from the standard state and act with an understanding of the cause-and-effect relationship between their actions and the reaction of the equipment.

Solution

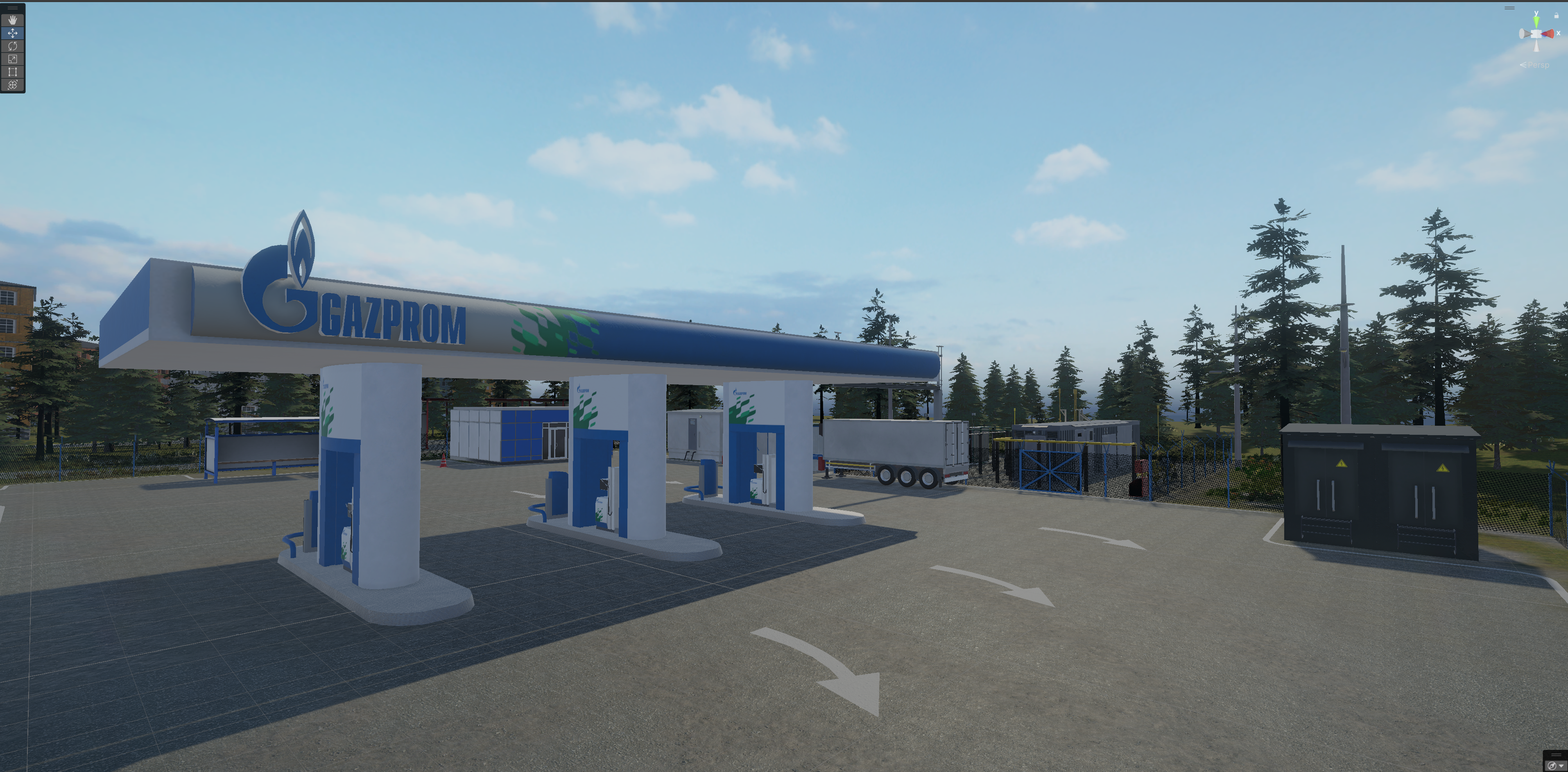

The virtual laboratory is a 3D model of a CNG filling station, equipped with a set of interactive control tools and a series of training programmes designed to simulate real-world scenarios for users.

CNG filling stations represent one of the common types of compressor stations situated at the final point of the gas distribution system. It is employed for the purpose of refilling high-pressure cylinders in vehicles that are powered by methane combustion.

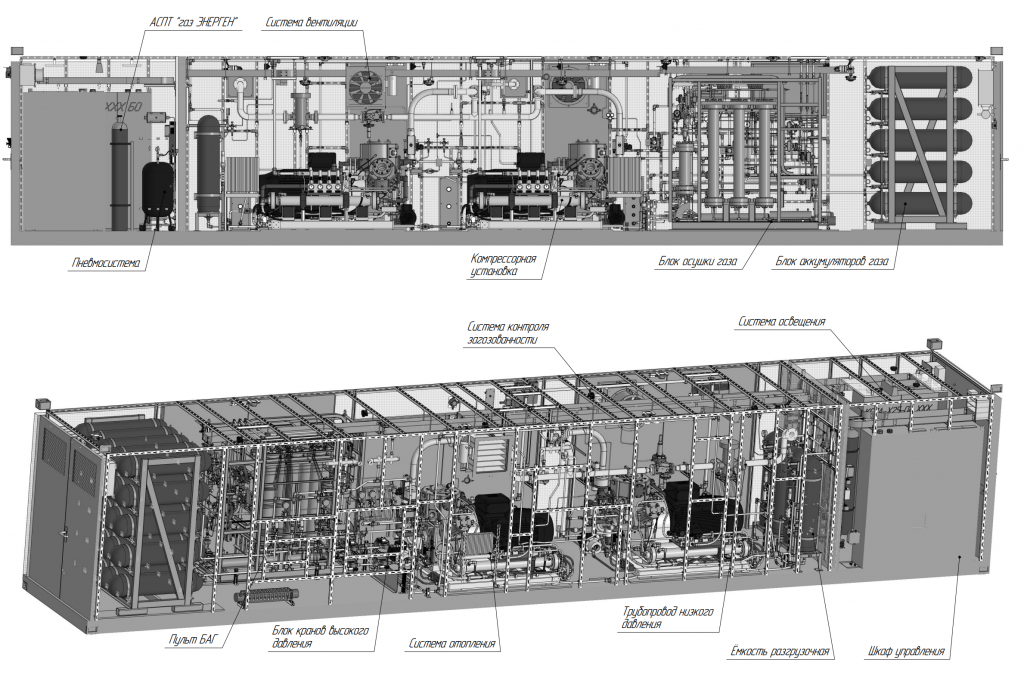

The VR application simulates the operation of CNG compressor equipment and auxiliary systems. The primary objective of the application is to facilitate the maintenance of the compressor unit of the CNG filling station. Consequently, the model of the gas block container and its contents is designed with a high degree of detail. They include a unit for connection to the municipal gas network (pressure 1.2 MPa), a dehydration system, gas cylinder systems for compressed natural gas (CNG) storage, air-cooling units, six fuel dispensers, and other components.

3D modeling

The models are highly detailed and realistic, accurately reproducing the main components and architectural features of the compressor station. They are based on a real Gazprom Gazomotornoye Toplivo facility, namely the CNG filling station-22 in St. Petersburg.

The developers undertook multiple site visits to the CNG filling station, utilizing a range of materials, including drawings, schematics, an illustrated parts list, photographic and video materials, presentations, and text descriptions, to develop the models.

The following 3D models have been developed: a gas block container, a block of inlet cranes, an air-cooled oil cooler, a complete transformer substation, a gas filling station, compressor units, a cold store, a building of input-distributing devices, and a service-operating block building.

Scenarios

Virtual training sessions are based on the technological regulations, bypass routes, and actions of shift operators at CNG filling station-22. The user operation scenarios were prepared by employees of the Higher School of Power Engineering of the Institute of Energy, SPbPU.

- Lab session scenarios

- Routine inspection of the CNG filling station equipment in operation. Shift handover.

- Scheduled shutdown of CNG filling station with gas venting.

- Preparation for the launch of the CNG filling station after a scheduled shutdown.

- CNG filling station emergency shutdown.

- Normal shutdown without gas venting.

- CNG filling station launch. Filling the circuits with gas.

- CNG filling station shutdown for scheduled repair and maintenance.

- Manual shut-off and venting of pipeline sections.

- Repair service of the CNG filling station equipment (replacement of valves in compressor cylinders and alignment of the compressor with the drive).

Software

The project has been developed in two versions. One is designed for use with virtual reality tools, while the other, more lightweight version is intended for use with ordinary personal computers.

The first interaction option, as a consequence of its unconventional input-output mechanics, offers a heightened level of immersion and informativeness. However, it is more resource-intensive for the computer and necessitates the provision of additional hardware.

The version designed for use with standard input devices (keyboard, mouse) is simple and intuitive and has the advantage of conserving PC resources, as it does not require the rendering of two images simultaneously.

The software is designed to be used on multiple platforms. A versatile system for user interaction with interactive objects was developed on the basis of the cross-platform principle, with logic that is independent of the platform.

Technologies

| 3D Development Environment | Blender, Substance 3D Painter, Marmoset Toolbag |

| Software Development Environment | Unity, Visual Studio, JetBrains Rider |

| VR kits | HTC VIVE PRO, Oculus Rift S и другие гарнитуры, совместимые с OpenXR |

| Programming languages and frameworks | С# |

The ‘Maintenance and Repair of Piston Compressor and Auxiliary Equipment of the Automobile Gas Filling Compressor Station’ virtual training and demonstration system was developed as part of the Education Quality Improvement and Personnel Training Programme for Gazprom PJSC/Peter the Great St. Petersburg Polytechnic University (SPbPU).

The goal of this project is to improve the educational process in Gazprom's core training areas at the Higher School of Power Engineering of the SPbPU Institute of Metallurgy, Mechanical Engineering, and Transport.

Key contributors

- Project manager: M.V. Bolsunovskaya, Head of the Industrial Systems for Streaming Data Processing Laboratory at SPbPU

- Consultant: A.A. Drozdov, Head of the ‘Research of Compressors, Pneumatic Systems, and Gas Compression and Processing Facilities’ research programme at the Higher School of Power Engineering of the SPbPU Institute of Energy

Partners

- Gazprom PJSC, Gazprom Transgaz Saint Petersburg LLC

- Higher School of Power Engineering of the Institute of Energy of SPbPU