Super Compact Autonomous Robotic Automobile (SCARA)

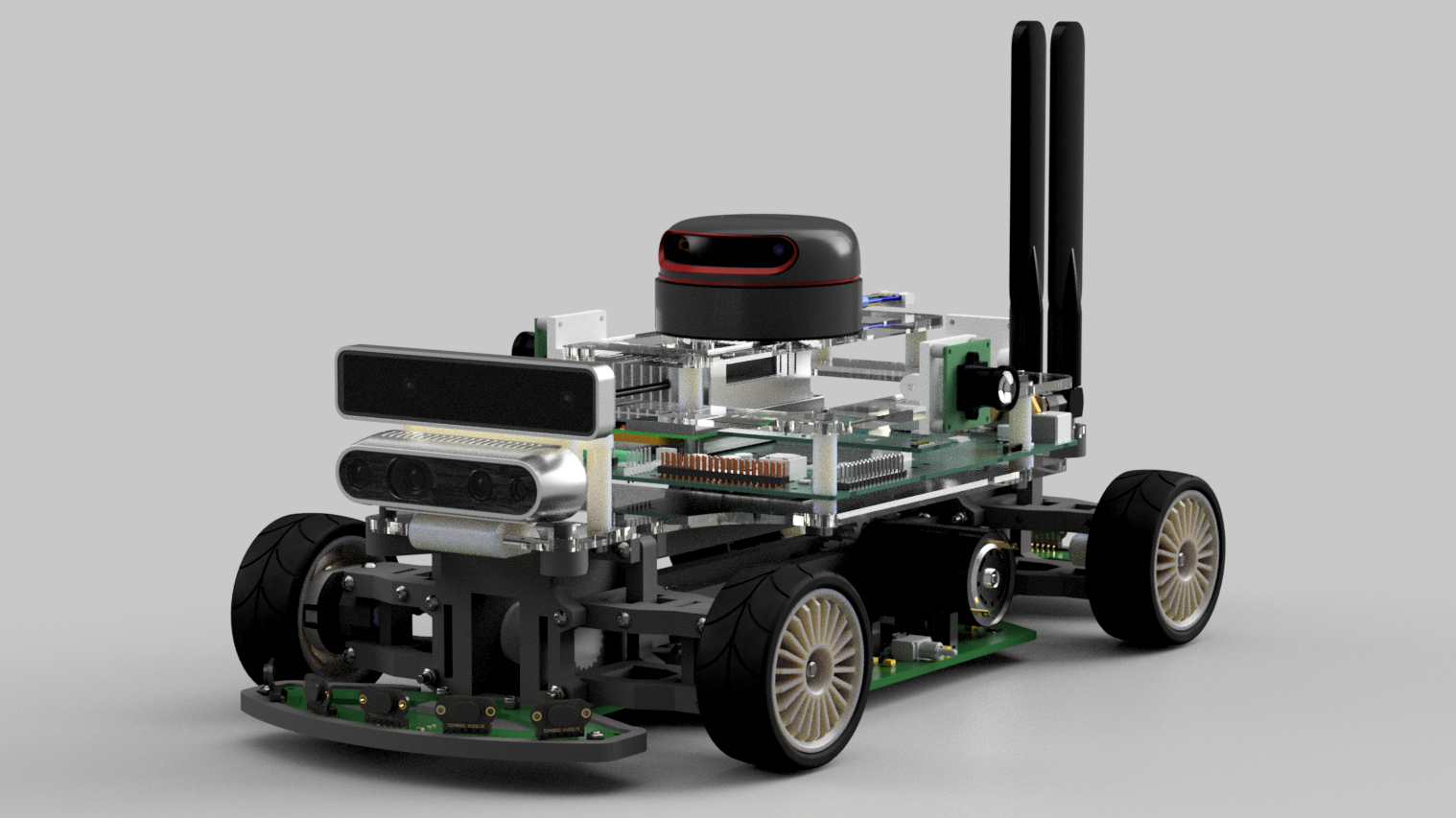

An ultra-compact model of an autonomous vehicle adapted for independent manufacturing and accompanied by a set of design documentation

Task

In accordance with the Advanced Engineering Schools project of the Ministry of Education and Science of the Russian Federation, which is designed to educate qualified engineering professionals for high-tech industries, Peter the Great St. Petersburg Polytechnic University has developed a programme for the establishment and further development of the "Digital Engineering" Advanced Engineering School (AES). The programme's objective is to collaborate with industrial partners engaged in system digital engineering.

As part of the SPbPU AES initiatives for professional development, training, and retraining of engineering personnel, not only training programmes are developed but also unique educational tools, including software and hardware/software simulators to imitate the performance of production tasks in the field of advanced manufacturing practices.

One such simulator is the Super Compact Autonomous Robotic Automobile (SCARA), a compact model of an autonomous vehicle designed for training professional engineers in the development of intelligent control systems for unmanned transport.

The model is intended for specialists at universities, research organizations, and training centres.

Solution

A comprehensive design documentation and a detailed model of the software and hardware complex have been developed, encompassing both physical and virtual embodiments.

- The model has been designed in such a way that it can be manufactured, modified, and customized by specialists at universities, research organizations, and training centres.

- The design of the wheels and the elements used in them are unified to the greatest extent possible.

- The number of prefabricated components is minimized. The majority of components are designed for 3D printing and laser cutting.

Structurally, SCARA is composed of two principal components:

- The wheels equipped with actuators, distance sensors, encoders, and a lower-level control system;

- The deck equipped with top-level control equipment, as well as lidar, one or two Intel Realsense smart cameras, surround-view cameras, and other sensors, depending on the configuration.

Details

Wheels

The wheels serve a dual purpose: they provide structural support for the SCARA's movement and house all the lower-level control electronics.

The objective of the structural work on the wheels was to facilitate manufacturing and eventual repair of the device to the greatest extent possible.

The following criteria were met when designing the wheel hardware:

- Maximum unification of design elements in order to simplify production and eventual repair of the wheels;

- Maximum number of flat elements with the same thickness so that they can be produced in two different ways if necessary (by 3D printing or laser cutting from plexiglass or ABS plastic sheet with subsequent drilling for fasteners);

- Vehicle chassis length scalability;

- Minimization of the number of structural elements;

- Reduction in the number of purchased elements, with the majority of construction elements being produced locally.

The lower-level software performs the following functions:

- Gathering distance sensor readings;

- Gathering encoder readings;

- DC motor control;

- Servo drive control;

- Performing an emergency stop if the distance sensors detect obstacles that threaten the safe operation of SCARA;

- Obtaining data on the SCARA's battery charge;

- Data exchange with the SCARA's upper level.

Deck

The basic configuration enables:

- Constructing and navigating terrain maps (e.g. using the SLAM method and odometry reading);

- Finding the shortest path to a point on the map;

- Avoiding dynamic and static obstacles.

Carrier PCB

The main PCB contains:

- STM32 controller with embedded control and distance sensor data processing system;

- Power subsystem providing the necessary control system equipment, including an STM32 controller, sensors, a DC motor, and a wheel rotation servo;

- Communication subsystem providing communication with the upper-level control system by means of a UART-USB converter;

- DC motor control subsystem (motor driver).

The prototype's moving component was constructed using standard radio-controlled model vehicle wheels as a basis. The prototype underwent a significant upgrade during the development process with the objective of improving maneuverability and reducing backlash in certain components of the wheel structure.

These dimensions are the most versatile. On the one hand, the model is able to accommodate the entire set of equipment required to fulfill its tasks. On the other hand, the model's compact dimensions facilitate its transportation and operation in confined spaces, such as small rooms, corridors, etc.

Technologies

| Programming languages and frameworks | C++, Python, ROS, Cartographer, C, CubeMx |

| OS | Linux |

| CVS | Git (Gitlab) |

| IDE | CLion, stm32cubeide, vscode |

The model was developed to meet the objectives of the "Best Practice Replication of Advanced Engineering Schools for Training and Retraining of Engineers" measure of the "Digital Modeling, Design, and Optimization of Production Processes and Activities of Real Sector Companies" project in accordance with the implementation plan of the "Digital Engineering" Advanced Engineering School programme.

The Advanced Engineering Schools federal project is implemented by the Ministry of Education and Science of the Russian Federation to train qualified personnel for high-performance and export-oriented economic sectors.