Solution for determining the adhesion of a bitumen film on gravels of different nature

Automated determination of the degree of adhesion of bitumen material to gravel based on analysis of the coating of the surface of gravel with bitumen using the digital image processing

Task

Oil bitumen used in road construction is characterized by a variety of compositions and complexity of the chemical structure, which depend both on the nature of the oil raw material and on the technology of its processing. Bitumen adhesion is understood as the strength of its adhesion to the skeleton-forming materials of the organomineral composite. An indicator of adhesion is the ability of bitumen to remain on the surface of gravel under the influence of an aggressive environment simulated by rotation in a bottle for a certain period of time.

At present, the degree of adhesion of bitumen to gravel is assessed according to GOST 12801-98 or EN 13614: 2011. The estimate methods indicated in them have serious downsides:

- The value of adhesion of bitumen to gravel is estimated by way of a visual expert assessment (Where repeat measurements of the same sample are carried out by another expert, variations in the value recorded may reach 20%.).

- No repeatability of experimental results is obtainable.

- No materials confirming the obtained experimental results are available.

The task of the developers was the creation of the hardware and software complex that would automate the assessment process and ensure high accuracy of the obtained experimental results.

Solution

The purpose of the development of the hardware and software complex is an automated assessment of the area of bitumen gravel coverings of different nature

Device features:

- Automated coverage area assessment

- Obtaining high-quality images of experimental results

- Storage of experimental results.

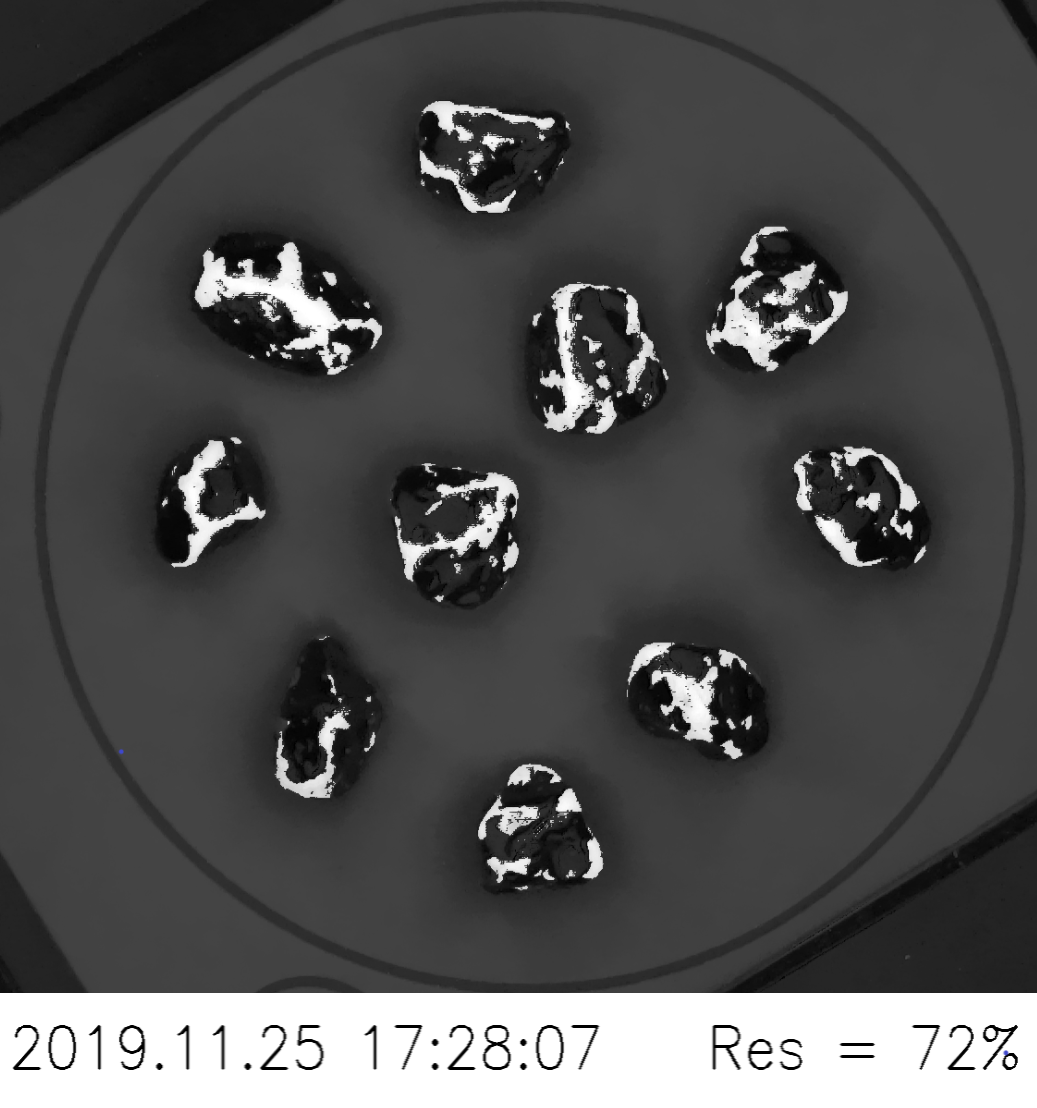

The device determines the degree of adhesion of bitumen to gravel by measuring the area of residual bitumen coverage of gravel after testing by rotation in a bottle. This measurement is performed by analyzing a digital image of gravel in a plane perpendicular to the axis of the lens.

Samples for analysis are placed in a specialized pull-out tray that provides the necessary positioning relative to the camera and light sources.

The sample analysis process involves two steps:

- Obtaining original images;

- Obtaining the final image and calculating the degree of coverage.

Advantages of the solution:

- Compliance with GOST 12801-98 and EN 13614: 2011;

- Exclusion of the human factor in the visual assessment of the coverage area;

- High accuracy and repeatability of experimental results;

- Continuous access to experimental results;

- Portability of the device.

Details

Project stages

- Creation of a methodology for quantitative determination of the degree of adhesion of bitumen material to gravel;

- Development of a hardware and software complex for automated laboratory analysis of the degree of adhesion of bitumen on gravels of different nature.

Research and development novelty

The segmentation algorithm is based on an analysis of pixel intensity. To increase accuracy, separation of objects into clusters is used; the dependence between pixels inside and among clusters (transition graphs) is also determined. Clusters are based on samples with varying degrees of bitumen covering (from 0 to 100%) taken from a statistical sample.

Qualitative and quantitative indicators achieved:

- One-time assessment of a set of samples (up to 10 pcs.);

- Reduction of the time for estimating the coverage area (up to 2 minutes);

- Storage and availability of high-quality digital photographs of samples with the assessment results (up to 250 pcs.);

- Reduction of measurement error (no more than 5%);

- Increased repeatability of the results (98-100%).

Currently, the device is installed and effectively operates at the customer company’s laboratory.

Technologies

| Software programming languages and frameworks | Python3, С89, HAL |

| Web-interface | HTML, framework Flask (Python3) |

| OS | Ubuntu 18.04 LTS х64 |

| Libraries | OpenCV-Python, Numpy, GPIO, Pyserial |

| IDE | Ру Charm Community Edition 2018.3.3 |

Intellectual Property

Project team

- Project manager: A. Ovsyannikova, A. Kuzmichev

- Developers: D. Kazakov, A. Korepanova

- Programmer-algoritmist: V. Rakova