A virtual training system was created to teach operations at the compressor station of an underground gas storage facility

The utilization of digital models of equipment and the completion of a series of practical tasks will facilitate the acquisition of competencies pertaining to the execution of routine maintenance and repair operations, as well as the identification and simulation of emergency scenarios.

The project has been carried out as part of the Education Quality Improvement and Personnel Training Programme (2022-2023) for Gazprom PJSC/Peter the Great St. Petersburg Polytechnic University (SPbPU). The project aims to optimize the educational process in disciplines relevant to Gazprom PJSC at the Higher School of Power Engineering of the Institute of Energy, SPbPU.

3D modeling and the software part were carried out by specialists from the Industrial Systems for Streaming Data Processing Laboratory of the SPbPU AES. The terms of reference and lab session scenarios were developed at the Graduate School of Power Engineering.

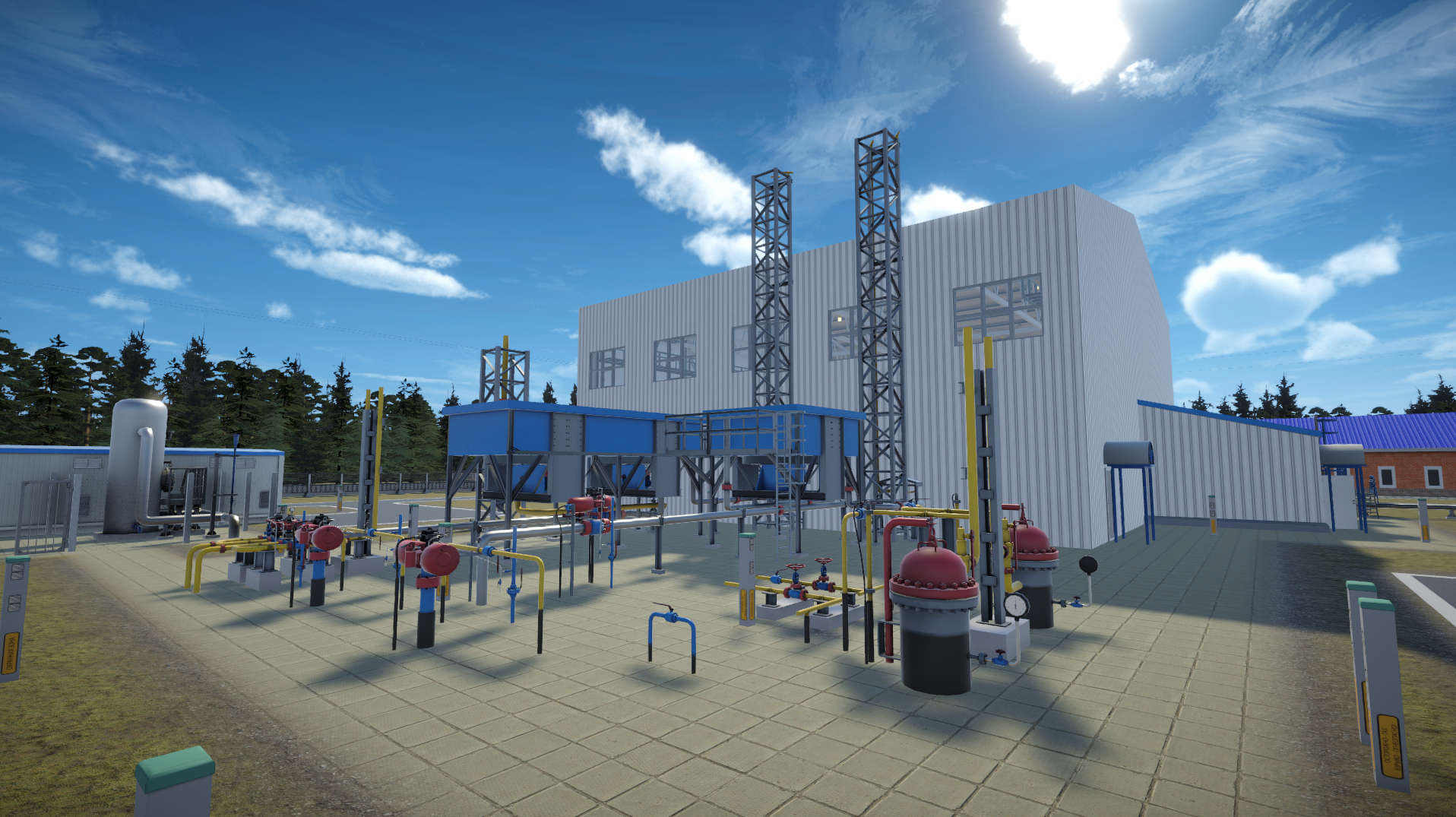

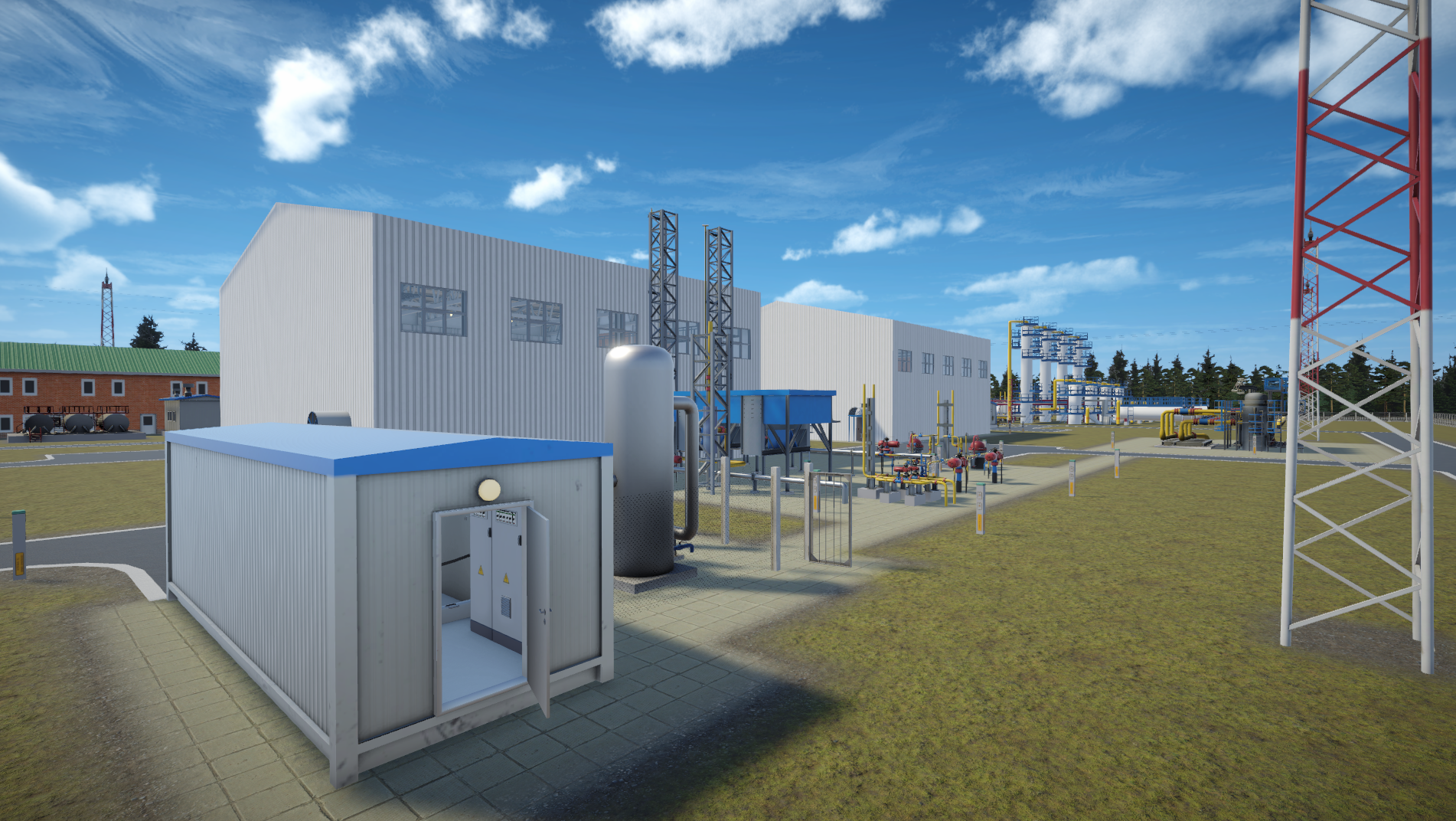

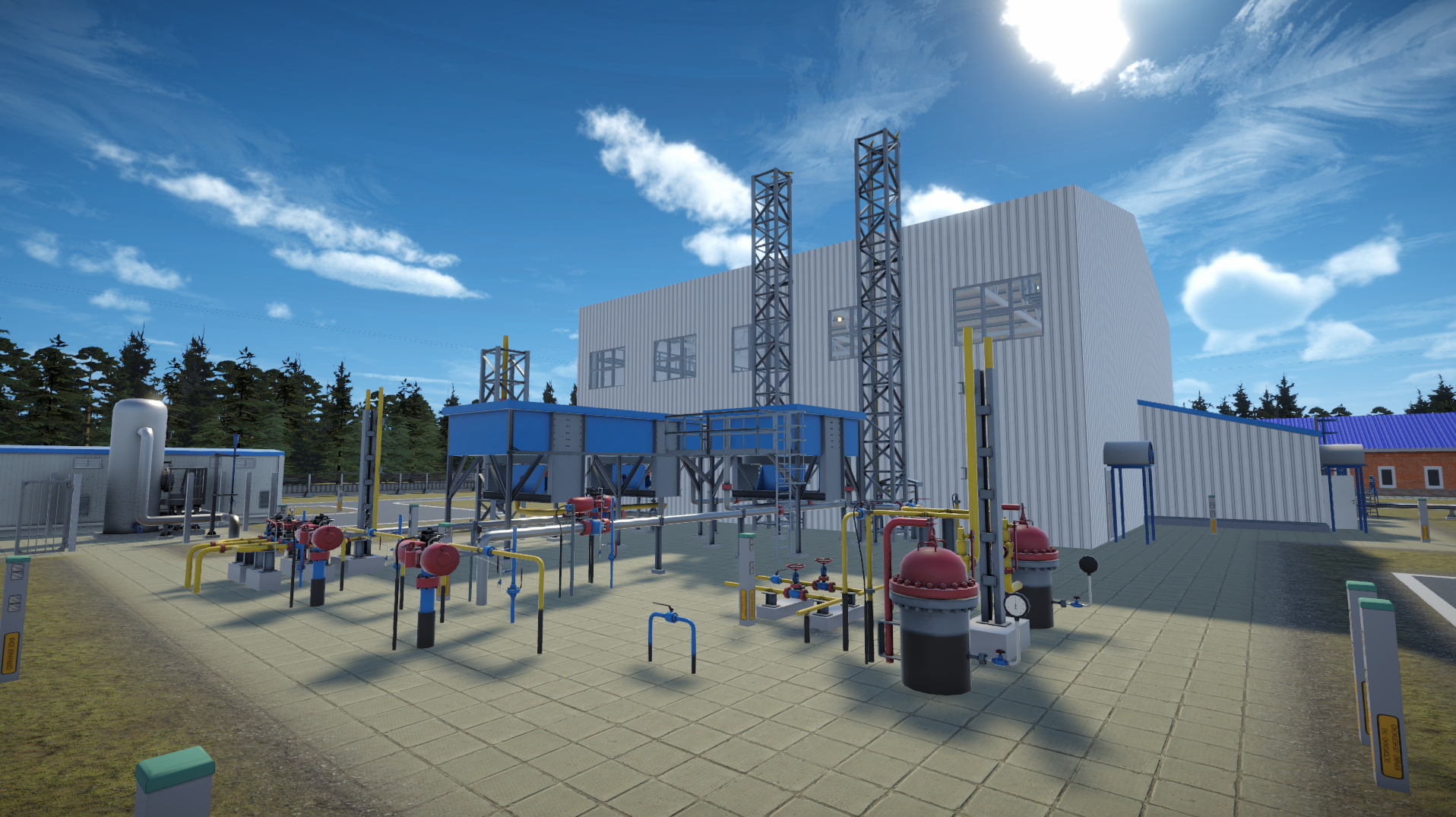

The training and demonstration complex is dedicated to the maintenance of compressor and auxiliary UGS equipment, malfunction troubleshooting, and operational safety at the facility. The 3D model of the underground gas storage station is enhanced with the incorporation of interactive control tools and a series of training scenarios designed for user engagement. The model simulates the operation of compressor equipment in both normal and emergency modes.

It also simulates the mechanical, thermal, and gas-dynamic processes that occur in the equipment in response to the operator’s actions. It is essential that users not only practice their steps in accordance with the instructions but also have a clear understanding of the effects that their actions have on the equipment. They must also be able to assess the extent to which the equipment is deviating from its normal state and determine the potential dangers associated with the situation.

The 3D models were developed on the basis of a real Gazprom UGS facility, namely the Nevsky Underground Gas Storage Division in the village of Kresttsy, Novgorod region. The models accurately represent the primary components and architectural features of the Nevskoye Underground Gas Storage Facility (UGSF).

The project is primarily concerned with the maintenance of gas pumping units (GPU) and systems associated with the compression of natural gas and its injection into the underground storage facility. Consequently, the model of compressor workshop No. 3, which incorporates engineering systems and three identical GPUs, is the most comprehensive within the virtual UGS facility. Additionally, auxiliary systems are modeled to the extent necessary for training purposes.

The scenarios employed in lab sessions are based on the technological regulations, bypass routes, and algorithms utilized by the Nevskoye UGSF operator in the course of their duties.

The system is prepared in two versions, one for use with the VR headset and manipulators, the other for keyboard and mouse control.

‘The utilization of virtual reality simulators in the field of education has demonstrated that they constitute an efficacious and visual tool for the preparation of students to engage with sophisticated power equipment. By accurately reproducing the appearance and functionality of real objects, they facilitate the practice of maintenance and repair of compressor equipment, internal combustion engines, and gas turbines. Additionally, they offer a more visual introduction to various components of gas transmission and storage systems,’ said Alexander Drozdov, Professor of the Higher School of Power Engineering at the SPbPU Institute of Energy.